Technology

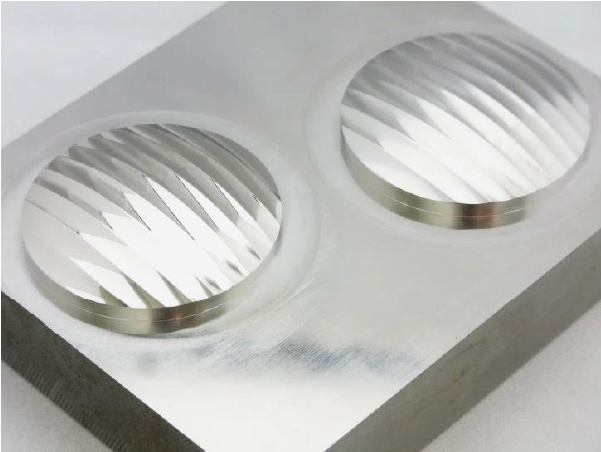

Finishing comparison of Automotive Light Lenses

Work material: STAVAX (52HRC)

Work size: 100x80mm

(Work shape: φ40x5.8mm)

Coolant: Oil mist / Water in-soluble

Machining time: 7hr 48min

Tool

MRBH230

●MUGEN COATING PREMIUM for hardened steel and unique cutting edge realize excellent chipping resistance and suppress chattering to improve finishing surface.

●Applicable for hardened steels up to 65HRC.

●Lineup to total 334 sizes.

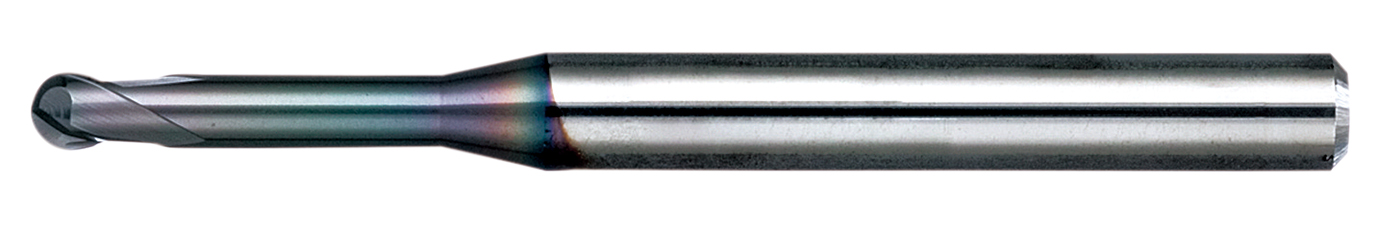

PCDRB

●Unique tool geometry makes stable surface.

●Polish-less machining become reality by nano-level roughness on profiling finish.

●Upgraded tool edge design makes stable high quality surface.

SSPB220

●Adopted spiral ball shape to improve sharpness of cutting edge.

●Adopted cutting edge shape to improve the chipping resistance of cutting edge.

●When peripheral cutting edge makes contact with cutting surface,vibration occurs by an increase in cutting resistance and it affects tool life and cutting surface quality.The influence can be reduced by adoption of the strong back taper shape.

●Enlarged standard tool size up to R3 to extend application range.

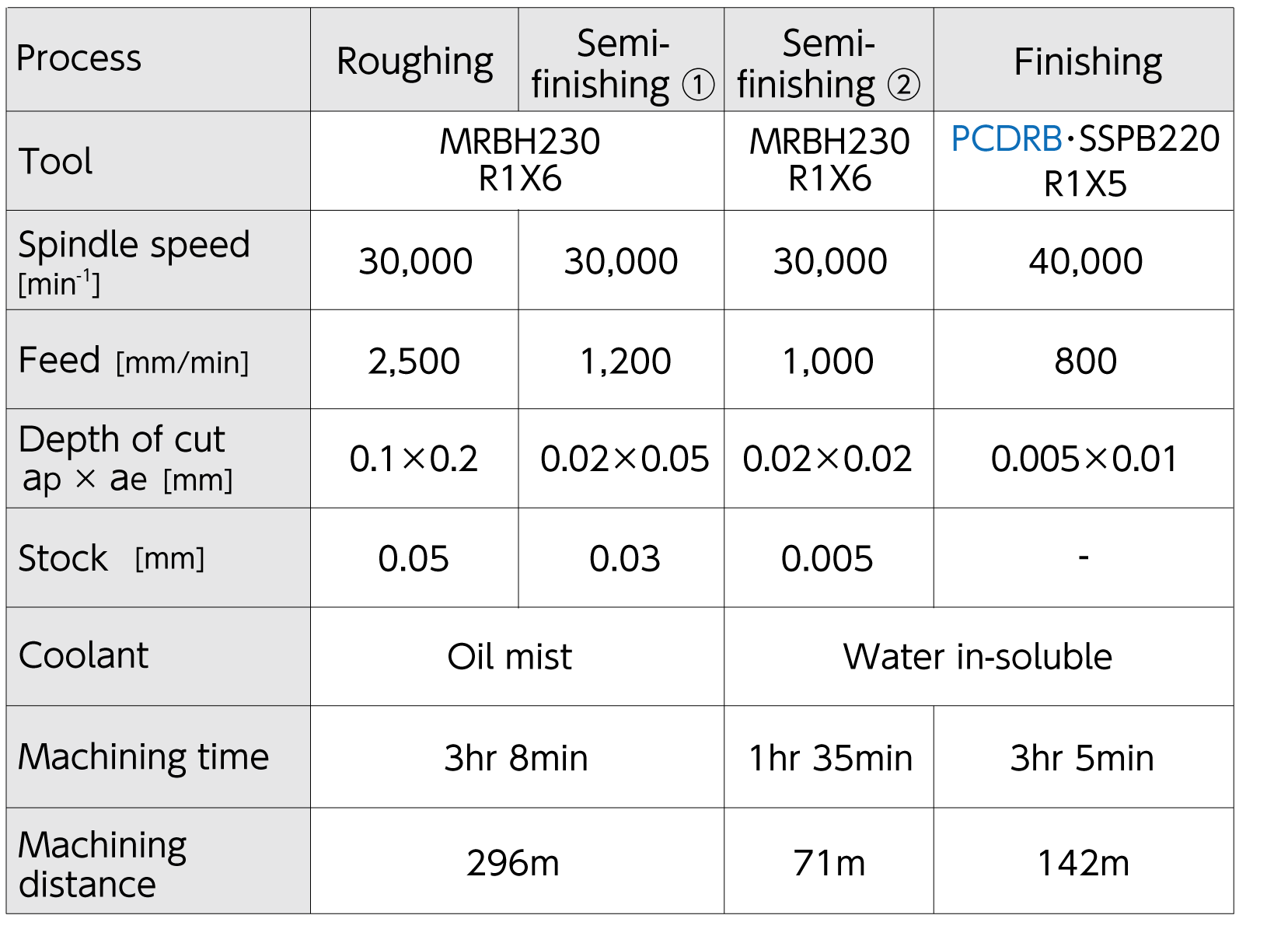

Cutting condition

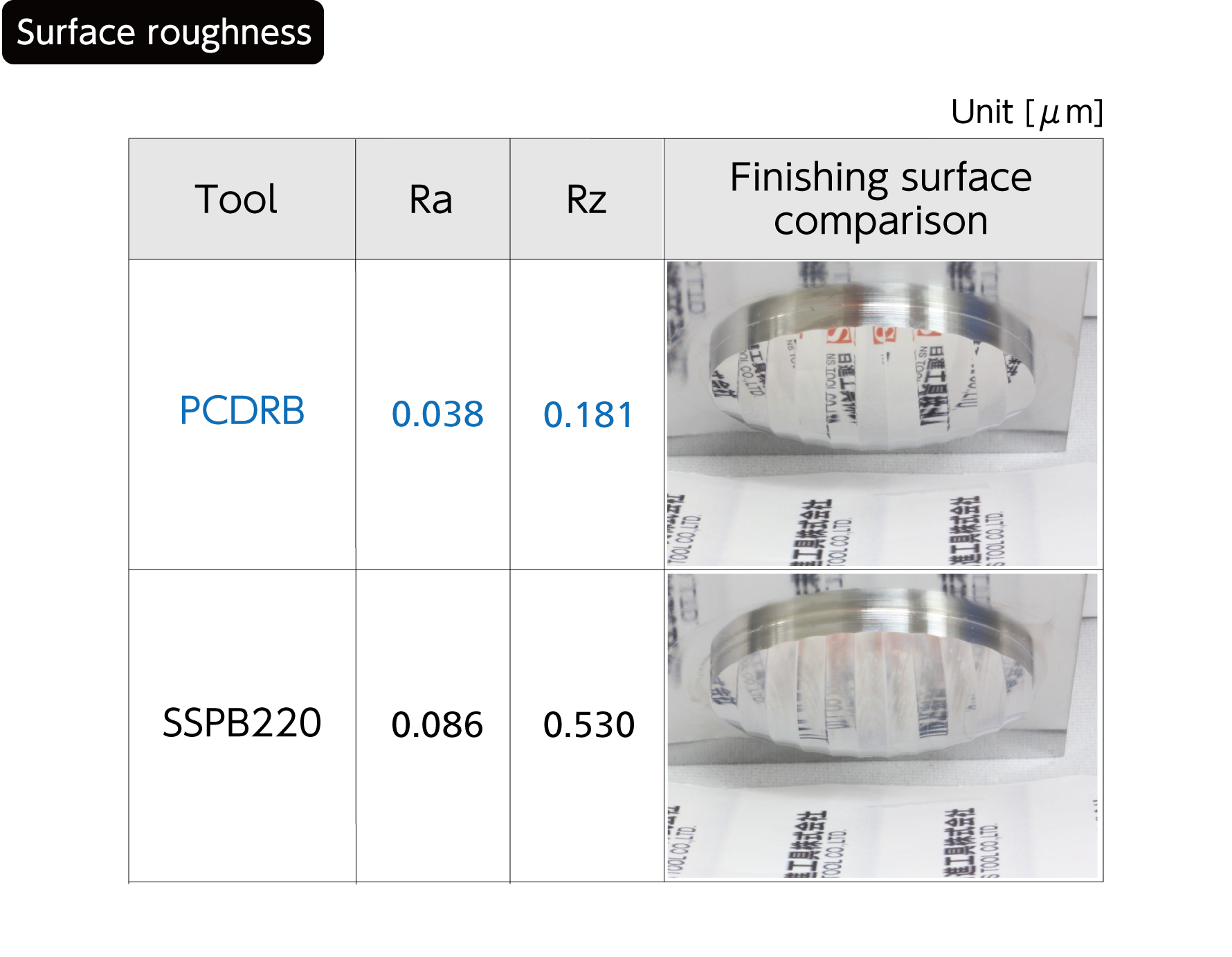

Result