Technology

Reflector Model

ELMAX / 60HRC

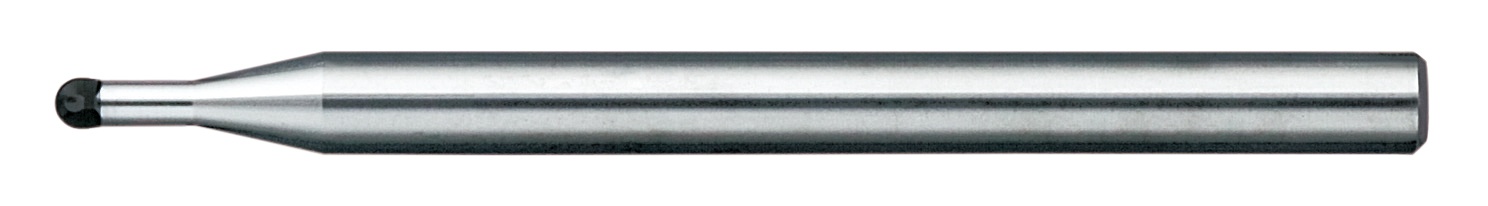

SFB200 / CBN Super Finish Ball End Mill

Work size: 20×20(mm)

Material: ELMAX 60HRC

Cutting time: 19 hr 10 min

Sharpened edge at R-center improves shearing ability!

Save significant time at finishing process.

Tool

SFB200

•Sharpened edge at R-center improves shearing ability.

•Continuous 10 hours machining on hardened steel of 60HRC.

•Long-lasting high surface accuracy Rz1.0um.

•Save significant time at polishing process.

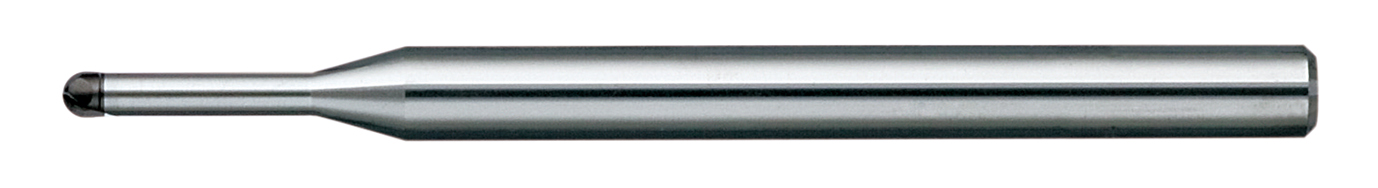

SSBL200

•Lineup of CBN tool with long neck applicable to deep milling, available 25 sizes in total.

•Enables milling more deeply by long effective length up 10mm comparing with conventional CBN tools.

•Enables wider application for milling by long neck in addition to long life and accurate finishing.

•Standardized in R0.05 at smallest.

•Unique flute design with R-accuracy ±0.003 prevents chipping!

MSBH230

•Standard ball end mill for hardened steels and suitable for finishing process.

•Applicable for hardened steels up to 68HRC.

Cutting Conditions

| Cutting process | Roughing | Semi-finishing | Finishing | |||

| Tool | MSBH230 R0.2 |

SSBL200 R0.2×1.2 |

SFB200 R0.2×1 |

|||

| Spindle speed (min-1) |

40,000 | |||||

| Feed (mm/min) |

800 | 700 | 400 | |||

| Depth of cut ap×ae(mm) |

0.015×0.05 | 0.005×0.01 | 0.004×0.002 | |||

| Cutting length (m) |

119 | 61 | 268 | |||

| Coolant | Oil mist | |||||

| Cutting time | 3 hr 23 min | 2 hr 10 min | 13 hr 37 min | |||

Comment

CBN-utilized design realized more than 10 hours of continuous finishing process to high hard material as 60HRC.

Surface roughness was Rz 79.6 nm and Ra 13.1 nm.