Technology

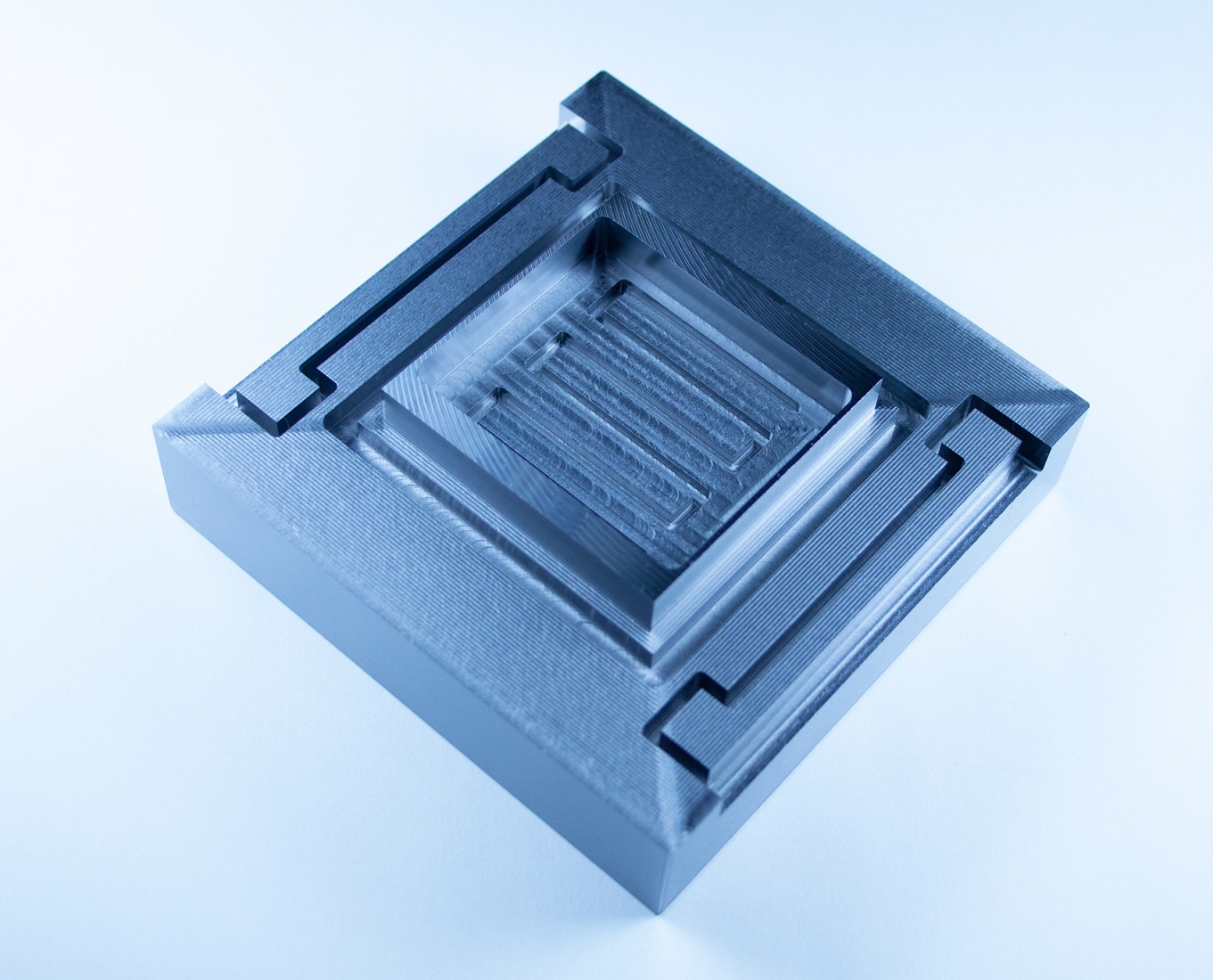

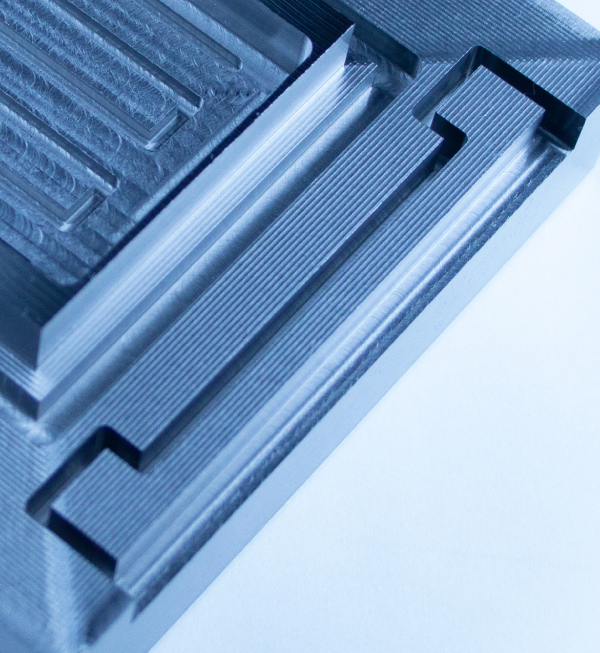

MSCZ440 (S50C) High efficient milling sample

Work size : 100×100×30mm

(Cutting depth : 14mm)

Material :S50C

Total cutting time : 23min

Tool

MSCZ440

●Unequal flute spacing, unequal helix angle and high rigid end profile design to minimize chatter realize high efficient machining.

●New developed special edge profile realized multi-functional performance of side milling, slot milling and drilling approaches on carbon steels.

Milling Conditions

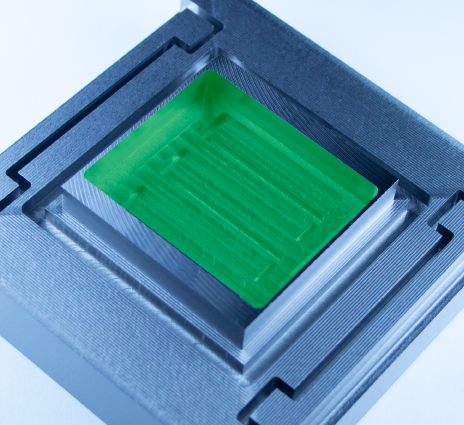

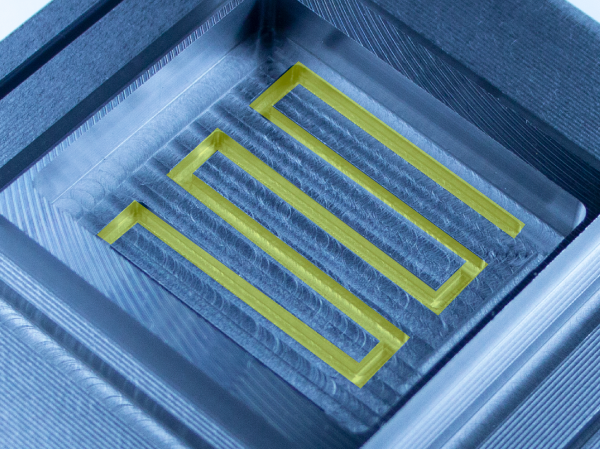

①Center pocket part (Depth 8mm)

Milling part in green

| Cutting process | ||||||

| Roughing | Finishing | |||||

| Approache | Side | Bottom | Side | |||

| Drilling | Slot | Interpolation (First cycle) |

||||

| Spindle speed (min-1) |

7,000 | 7,000 | 7,000 | 8,500 | 8,500 | 8,500 |

| Feed (mm/min) |

300 | 1,100 | 1,700 | 1,700 | 1,200 | 1,200 |

| Depth of cut ap(mm) |

ap:4※ | ap:4※ | 4×1 | 7.95×0.8 | 8×0.1 | 0.05×2 |

| stock | Side:0.1 Bottom:0.05 |

- | ||||

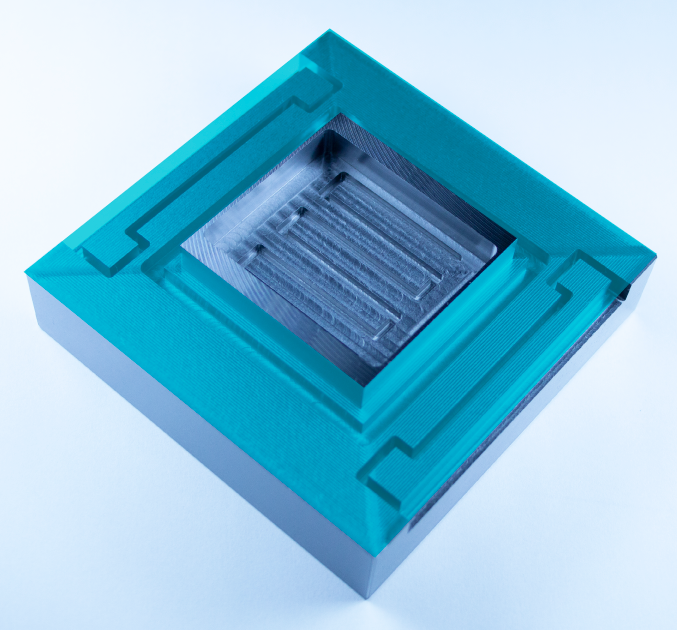

②The outer periphery part (Depth 8㎜)

Milling part in blue

| Cutting process | ||

| Roughing | Finishing | |

| Side | Side | |

| Spindle speed (min-1) |

8,500 | 8,500 |

| Feed (mm/min) |

1,700 | 1,200 |

| Depth of cut ap(mm) |

8×0.8 | 8×0.8 |

| stock | Side:0.1 | - |

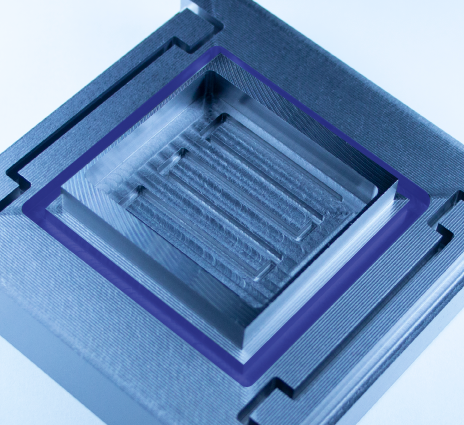

③Blind slot part(Width 4.2㎜ Depth 4㎜)

Milling part in purple

| Cutting process | Roughing | Finishing | |

| Drilling | Slot | Side | |

| Spindle speed (min-1) |

7,000 | 7,000 | 8,500 |

| Feed (mm/min) |

300 | 1,100 | 1,200 |

| Depth of cut ap(mm) |

ap:3.95 | ap:3.95 | 4×0.1 |

| stock | Side:0.1 Bottom:0.05 |

- | |

④Through groove(Width 2.2㎜ Depth 6㎜)

| Cutting process | Roughing | Finishing | ||

| Slot | Side | Side | Bottom | |

| Spindle speed (min-1) |

10,000 | 11,000 | 11,000 | 11,000 |

| Feed (mm/min) |

500 | 900 | 650 | 650 |

| Depth of cut ap×ae(mm) |

ap:2 (3 times milling)※ |

5.95×0.2 | 6×0.1 | 0.05×1 |

| stock (mm) |

Side:0.1 Bottom:0.05 |

- | ||

※The final pitch is ap:1.95.

⑤Blind slot part(Width 2.2㎜ Depth 2㎜)

Milling part in yellow

| Cutting process | Roughing | Finishing | |

| Drilling | Slot | Side | |

| Spindle speed (min-1) |

10,000 | 10,000 | 11,000 |

| Feed (mm/min) |

100 | 500 | 650 |

| Depth of cut ap×ae(mm) |

ap:1.95 | ap:1.95 | 2×0.1 |

| stock | Side:0.1 Bottom0.05 |

- | |