Technology

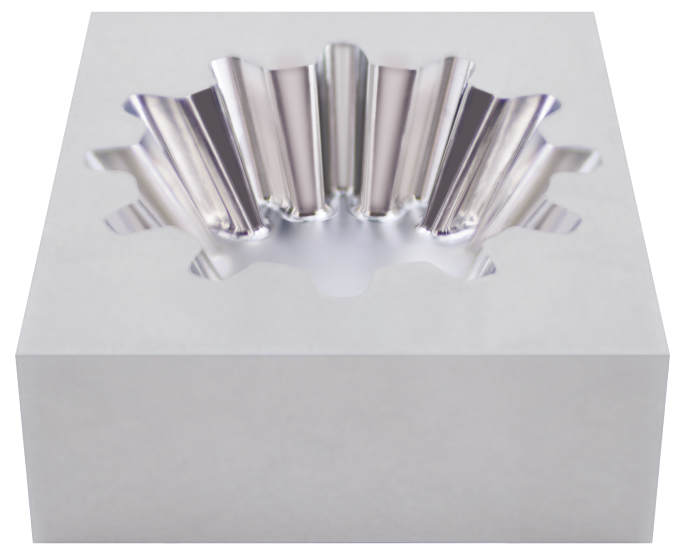

MRBSH330 Gear model

Even micro shape with small diameter also supports depth of cut and feed rate for high efficiency

Work material : YXR7(61.5HRC)

Work size : 50×50mm

Depth of cut : 10mm

Coolant : Oil Mist

Total machining time : 1hr45min

Tool

MRBSH330

●High-efficiency 3-flute ball end mill optimizes a shape of central edge and enables high depth of cutting.

●Even hardened steel of 45 to 70HRC can be machining with long tool life and high efficiency.

●R accuracy is ±0.005mm (R accuracy is based on a half value of actual diameter).

●Shank diameter tolerance , high accuracy type, is - 0.001 ~ - 0.003.

Cutting condition

| Process | Roughing | Semi-finishing | Finishing |

| Tool | MRBSH330 R1×6 |

||

| Spindle speed (min-1) |

20,000 | ||

| Feed (mm/min) |

2,400 | 2,400 | 1,200 |

| Depth of cut ap×ae(mm) |

0.225 × 0.3 | pf:0.09 | pf:0.05 |

| Stock (mm) |

0.03 | 0.01 | 0 |

| Time | 57min | 12min | 36min |

Result

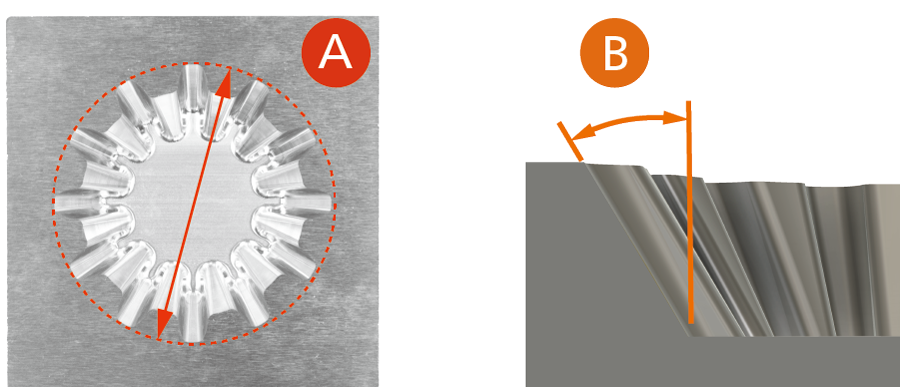

【Accuracy】

Unit [mm]

Width Width |

Inclined angle Inclined angle |

|

| Target | 37.073 | 30°45’ |

| Actual | 37.069 | 30°48’ |

| Error | -0.004 | + 0° 3’ |

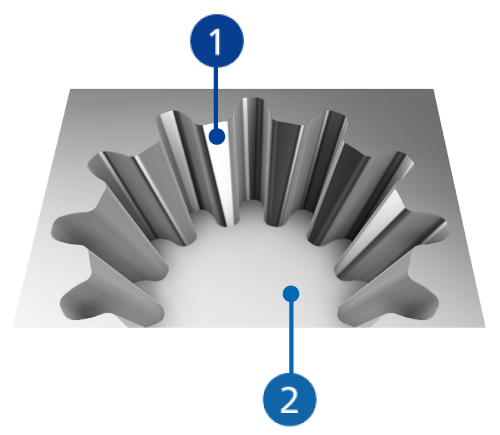

【Surface roughness】

Unit [μm]

|

|

|

| Ra | 0.26 | 0.41 |

| Rz | 1.75 | 3.69 |

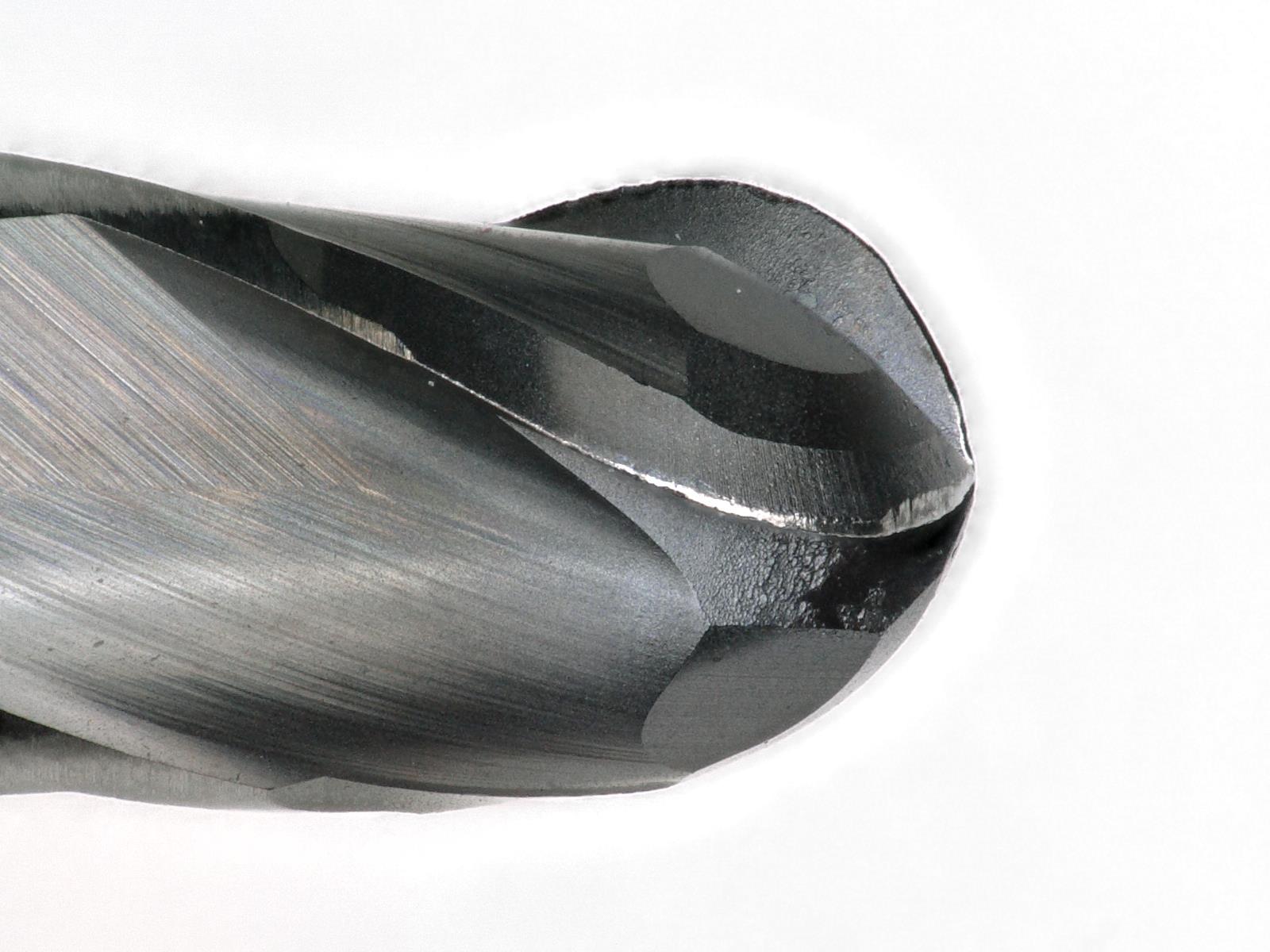

【Tool wear】

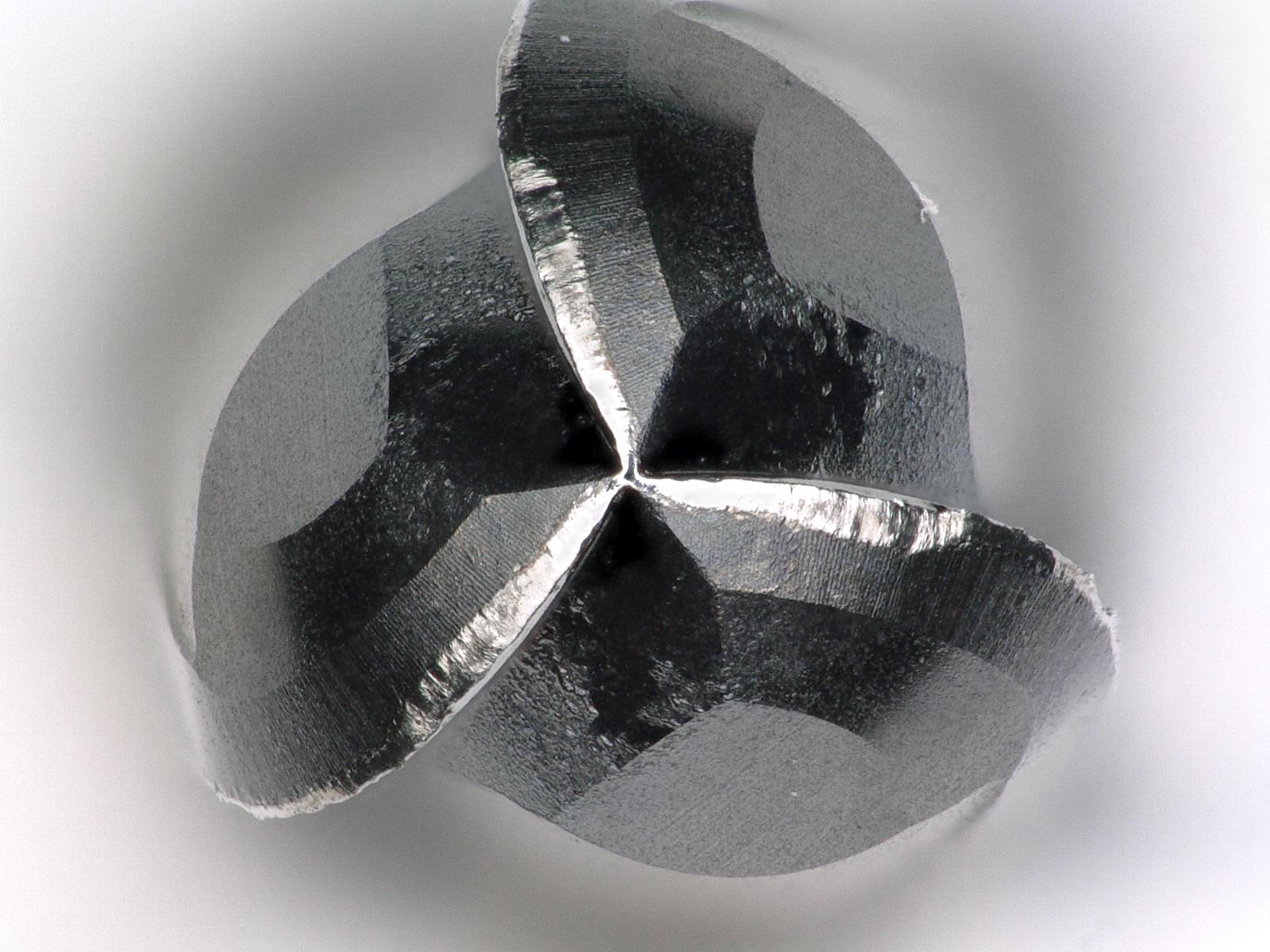

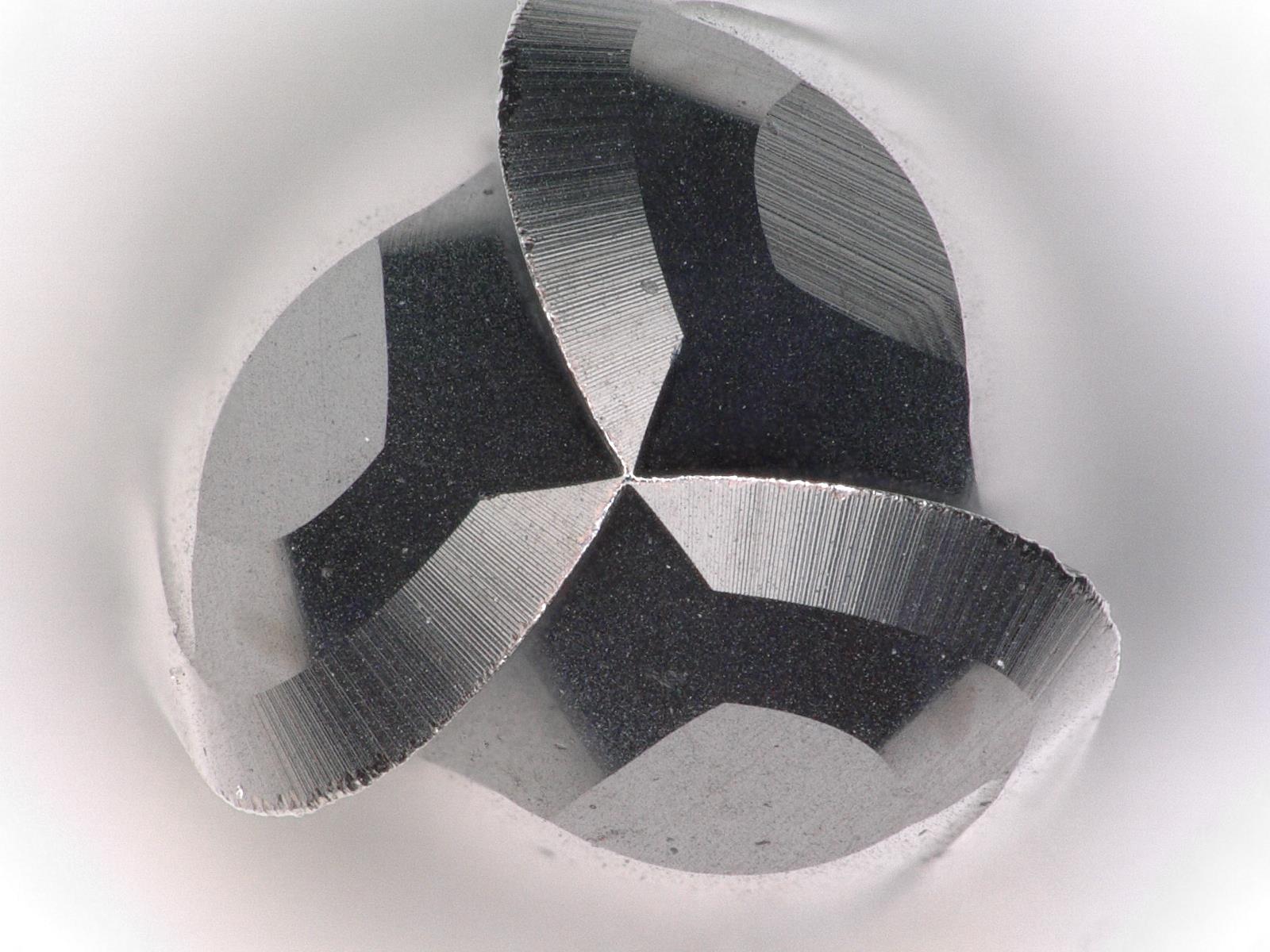

| Rake | Peripheral cutting edge | Center | Machining time | |

| MRBSH330 R1 × 6 Roughing |

|

|

|

57min |

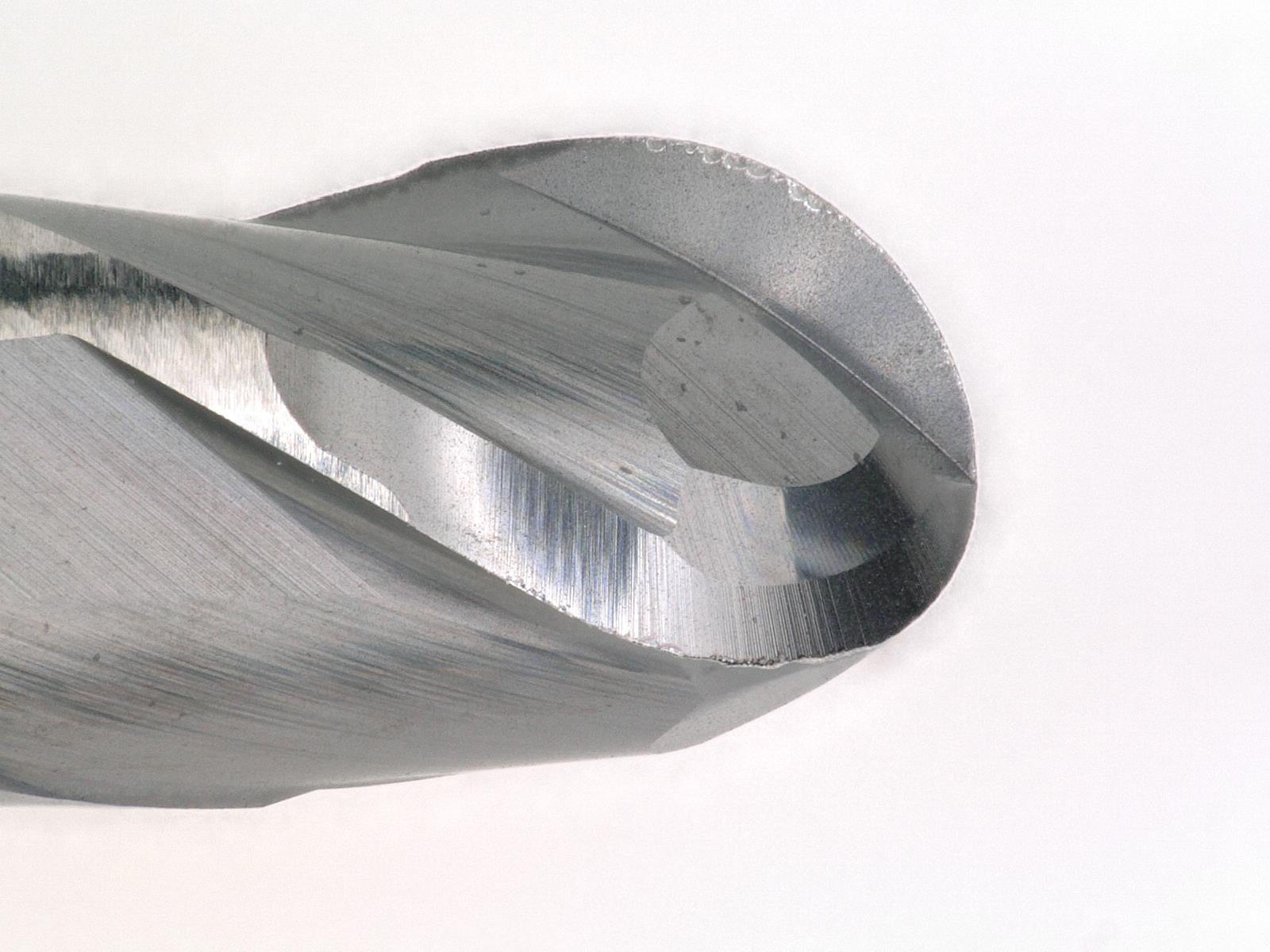

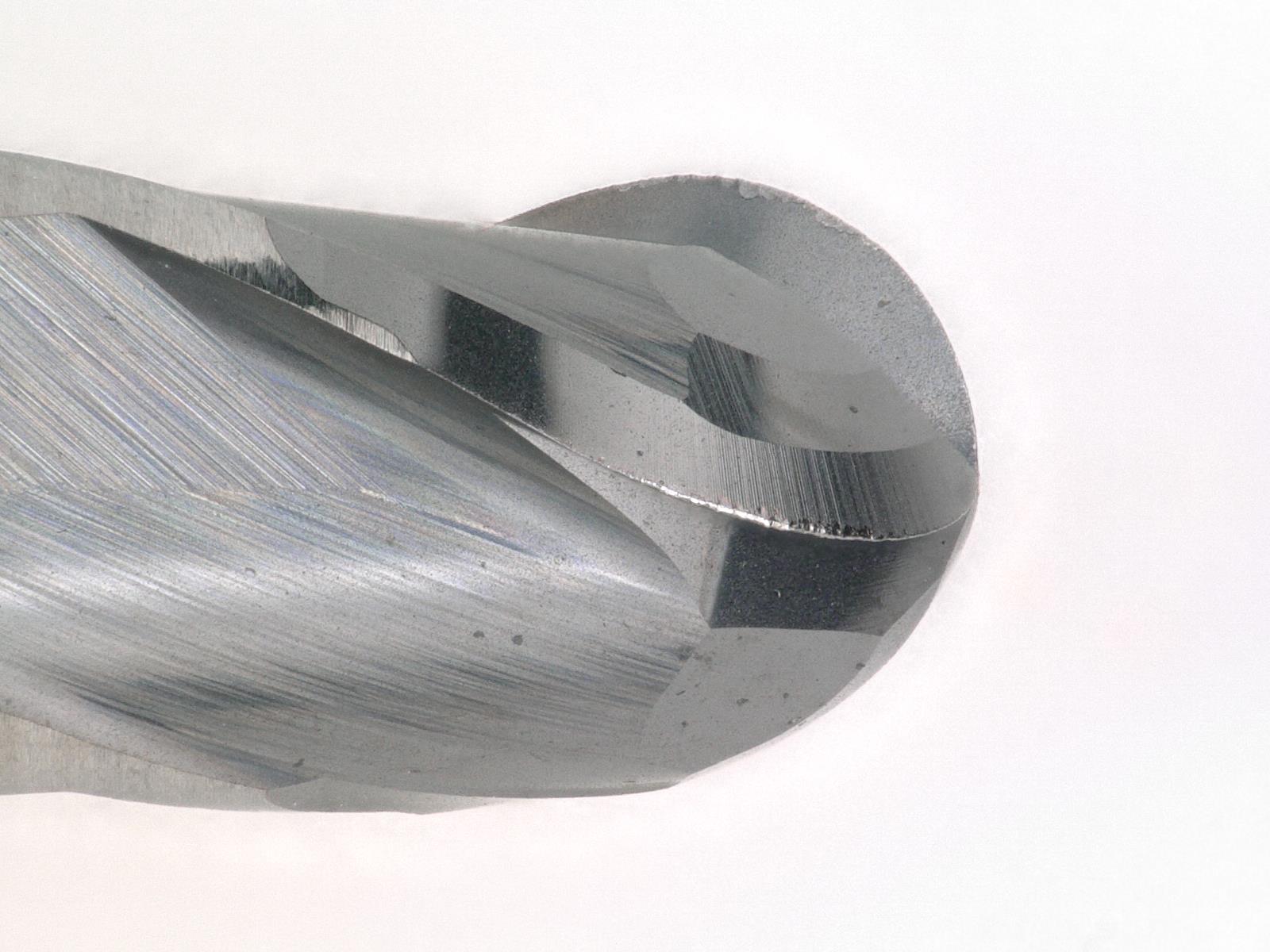

| MRBSH330 R1 × 6 Finishing |

|

|

|

36min |