SSPB220

CBN Super Spiral Ball End Mill

●Adopted spiral ball shape to improve sharpness of cutting edge.

●Adopted cutting edge shape to improve the chipping resistance of cutting edge.

●When peripheral cutting edge makes contact with cutting surface,vibration occurs by an increase in cutting resistance and it affects tool life and cutting surface quality.The influence can be reduced by adoption of the strong back taper shape.

●Enlarged standard tool size up to R3 to extend application range.

Material

CubicBoron Nitride

Cutting Possibility of Work Material Hardness

Up to 70HRC

Number of Flutes

2 Flutes

Helix Angle

20°

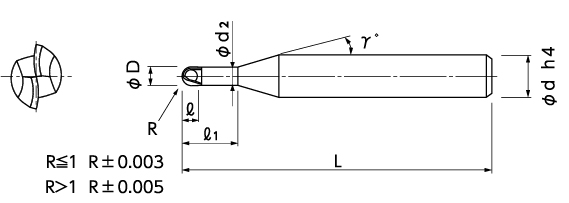

Conner

±0.003(R≦1) &

±0.005(R>1)

φd h4

Applications

3D Milling

Work Materials

Machinable indication by  ,

,

| Carbon Steel | Alloy Steel | Prehardened Steel | Hardened Steel | Stainless Steel | Heat Resistant Alloy | Aluminum Alloy | Copper | Resin | Graphite | Hard Brittle Material | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ~ 52HRC |

~ 60HRC |

~ 65HRC |

~ 70HRC |

||||||||||

| Carbon Steel | Heat Resistant Alloy |

|||

|---|---|---|---|---|

| Alloy Steel | Aluminum Alloy | |||

| Prehardened Steel |

Copper | |||

| Hardened Steel |

~ 52HRC |

Resin | ||

| ~ 60HRC |

Graphite | |||

| ~ 65HRC |

Hard Brittle Material |

|||

| ~ 70HRC |

Hard Brittle Material |

|||

| Stainless Steel | ||||

Machining Video