Technology

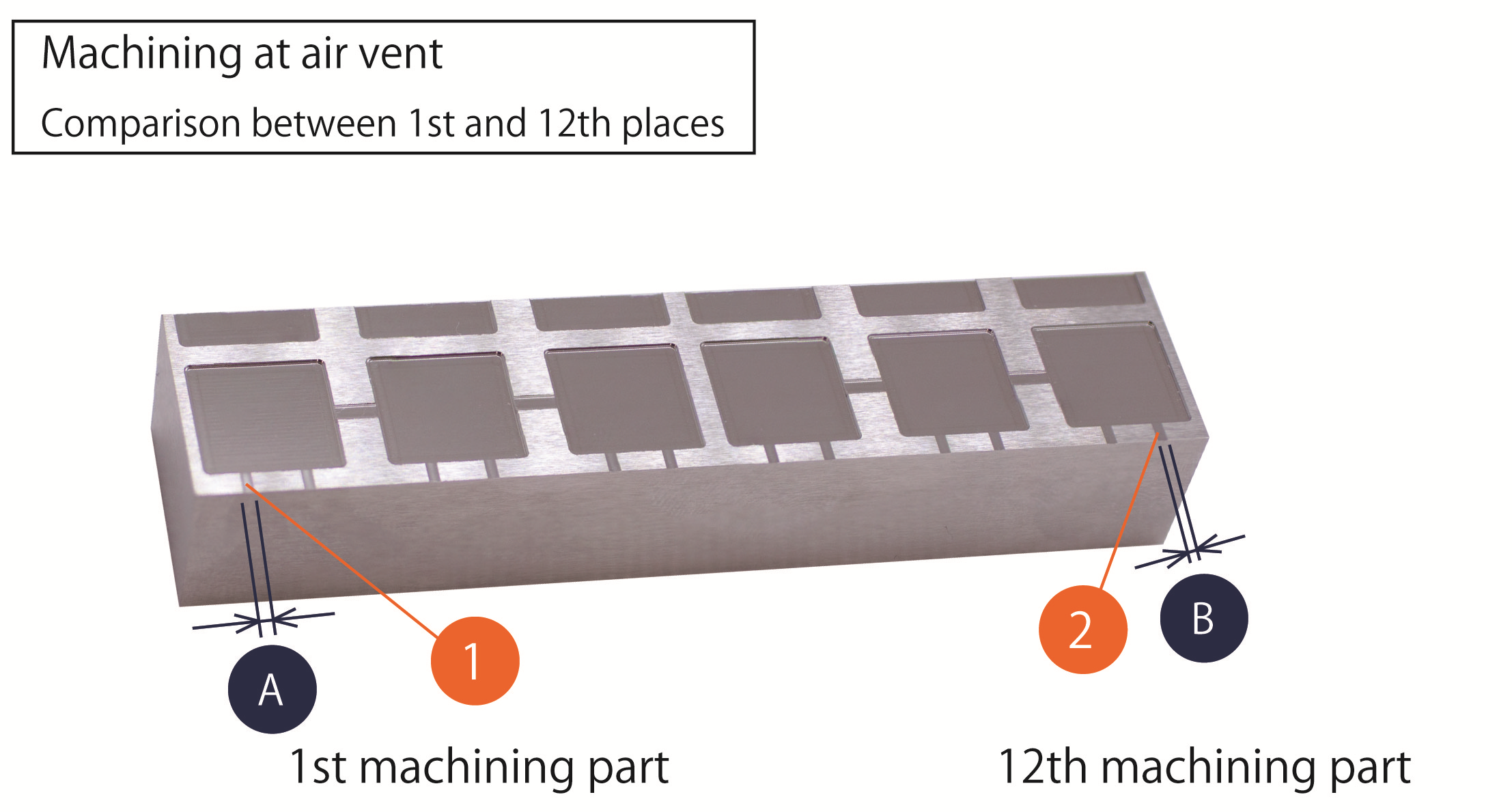

MHRSH430RSF Sealed mold

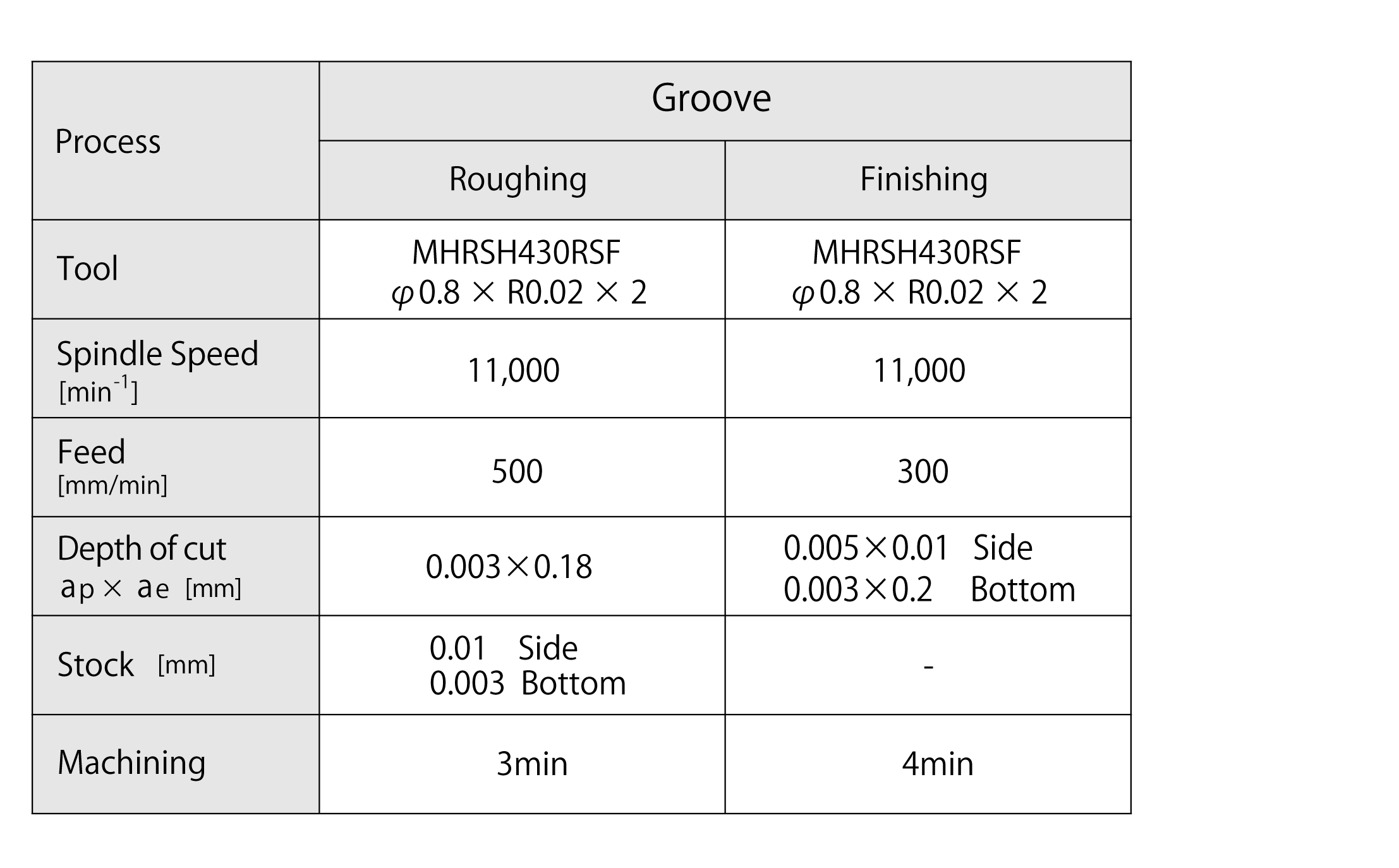

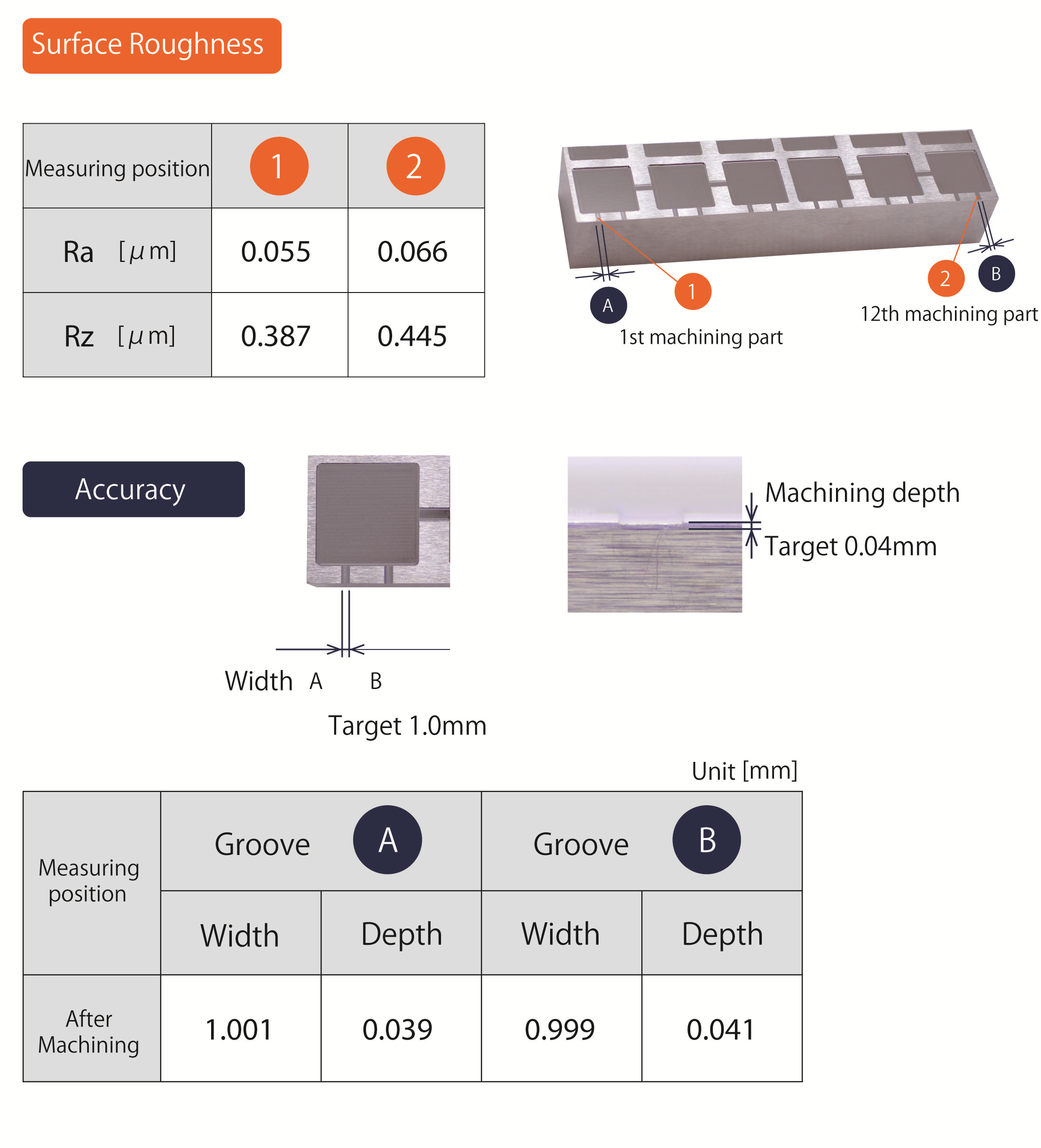

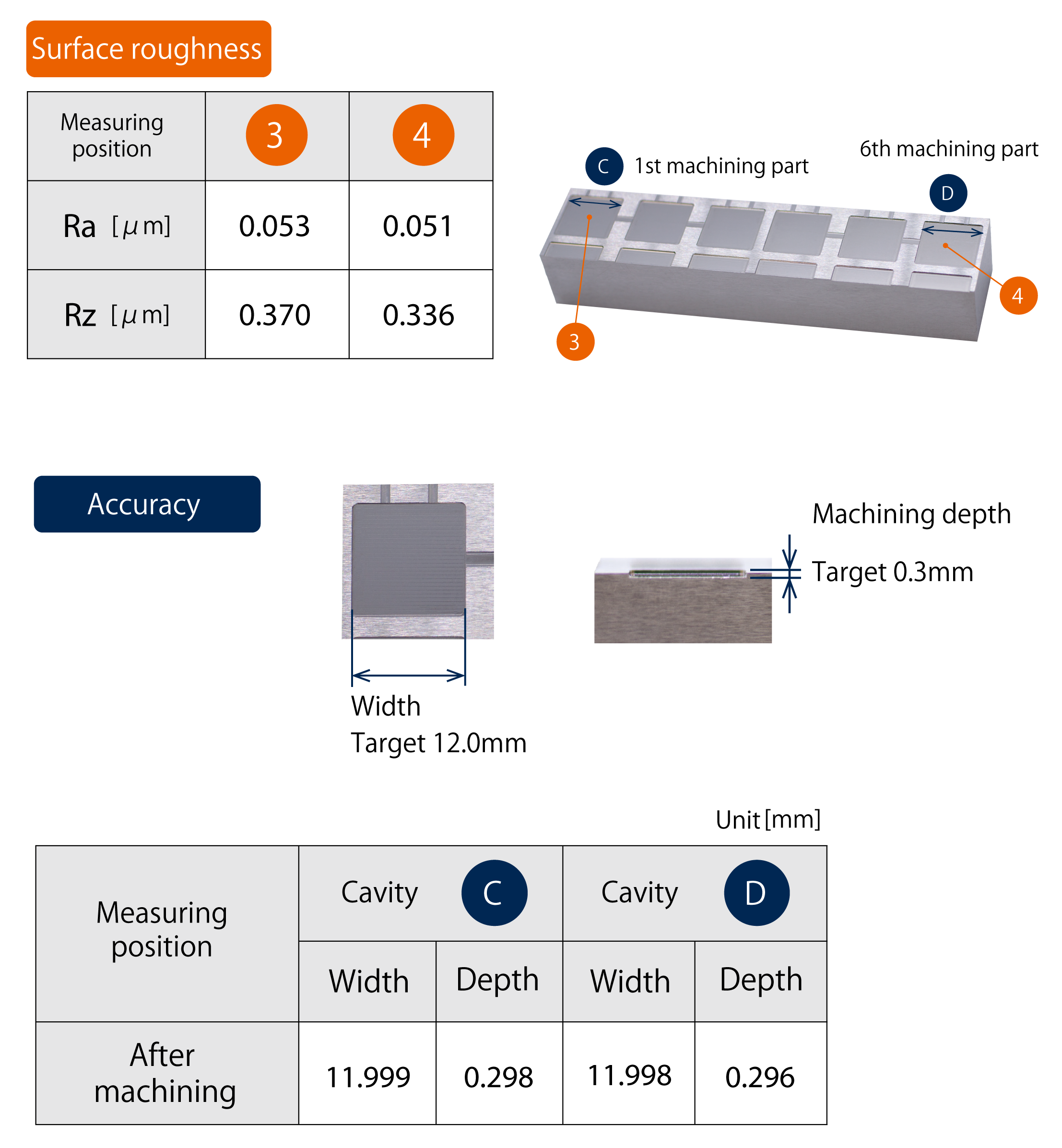

Realized stable dimension accuracy on machining hardened steels

By adopting wiper at the end cutting edge achieves high precision surface roughness on plane machining

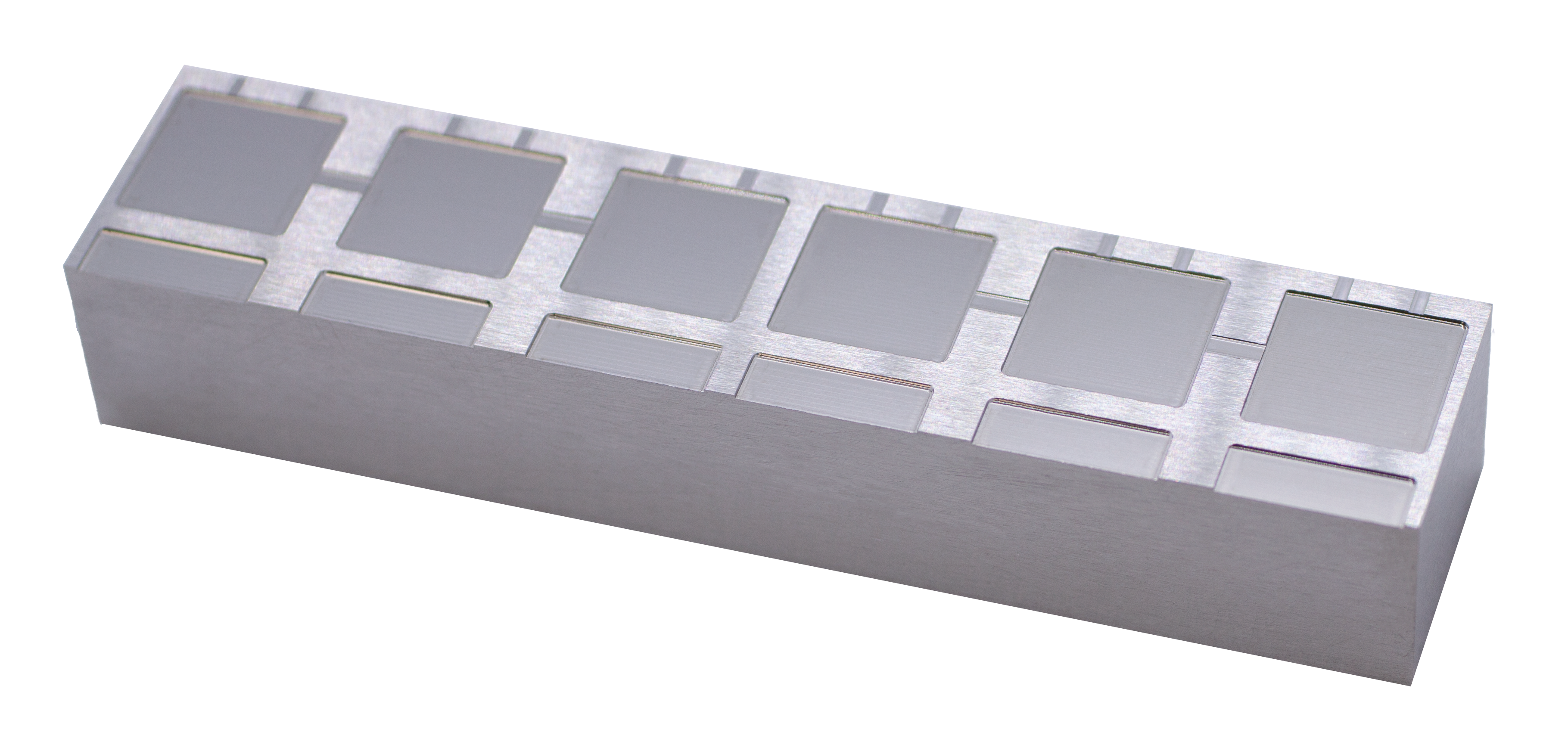

Work material : VANADIS23(63HRC)

Work size : 20×90×15mm

Machining depth : 0.3mm

Coolant : Oil mist

Total machining time : 1hr 44min

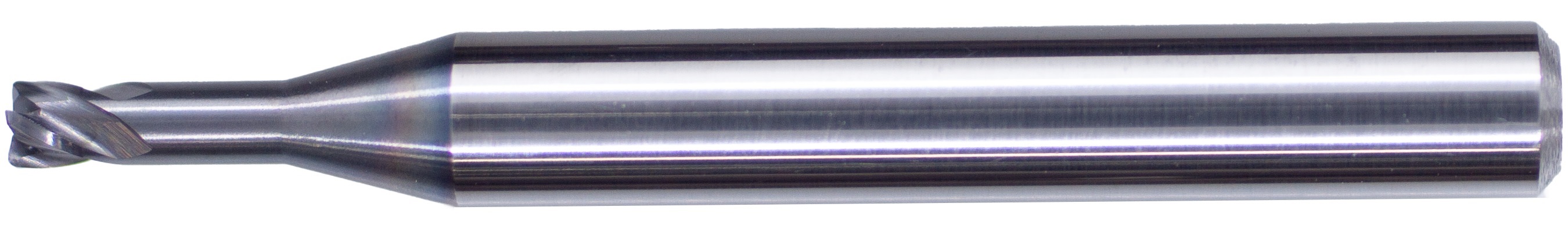

Tool

MHRSH430RSF

●MUGEN COATING PREMIUM Plus for hardened steels with strong back taper reduce chattering to realize long tool life and excellent finishing surface.

●4- flute end mill for high efficiency machining.

●The smallest diameter of 4- flute end mills standardizes from Φ0.1, total 131 sizes.

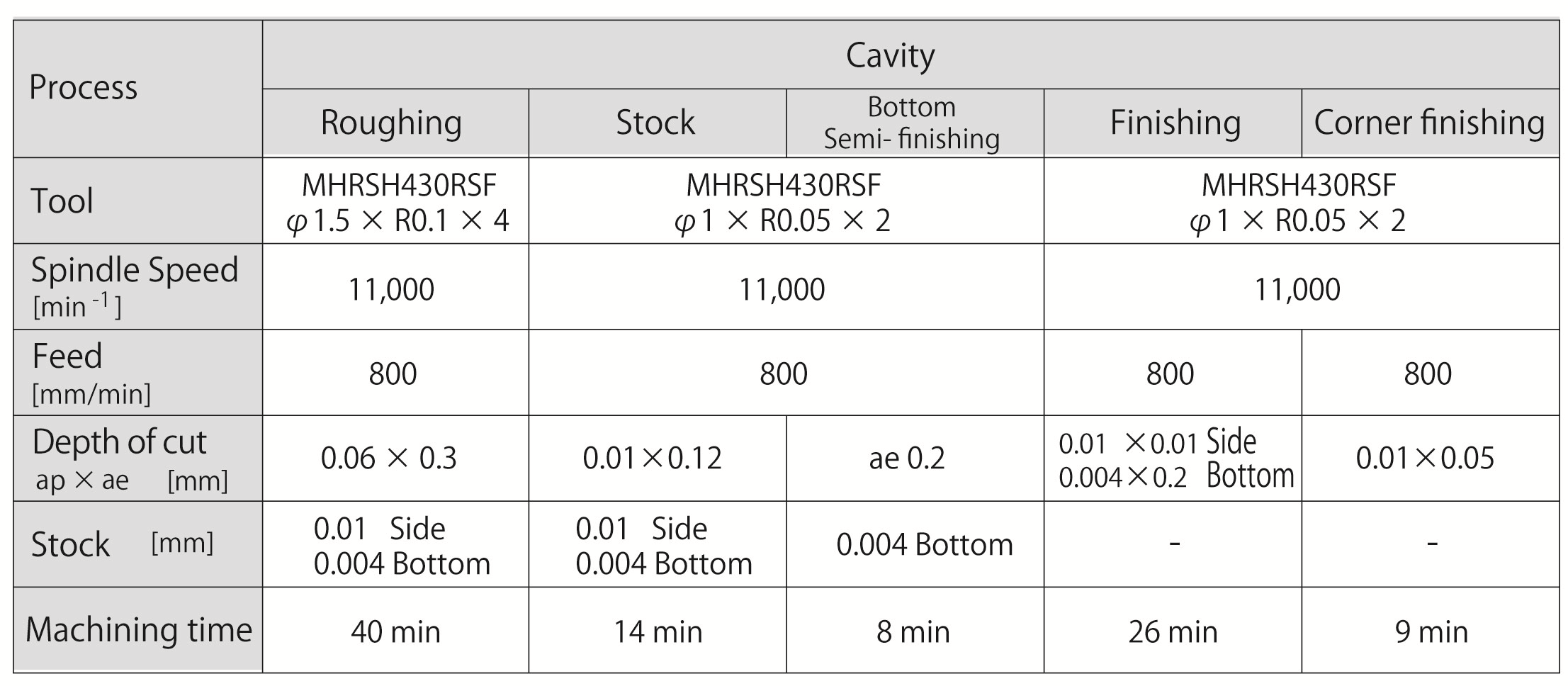

Cutting condition and result