Technology

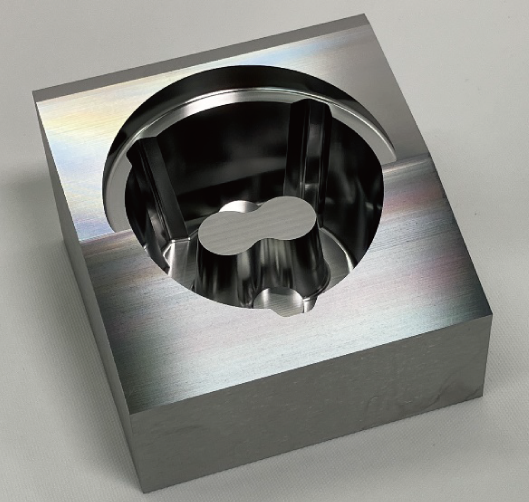

MLFH330 EV Connector

Work material: HPM38 (31HRC)

Work size: 70x70x45mm

Max machining depth: 35mm

Coolant: Oil mist

Total machining time: 8hr 20min

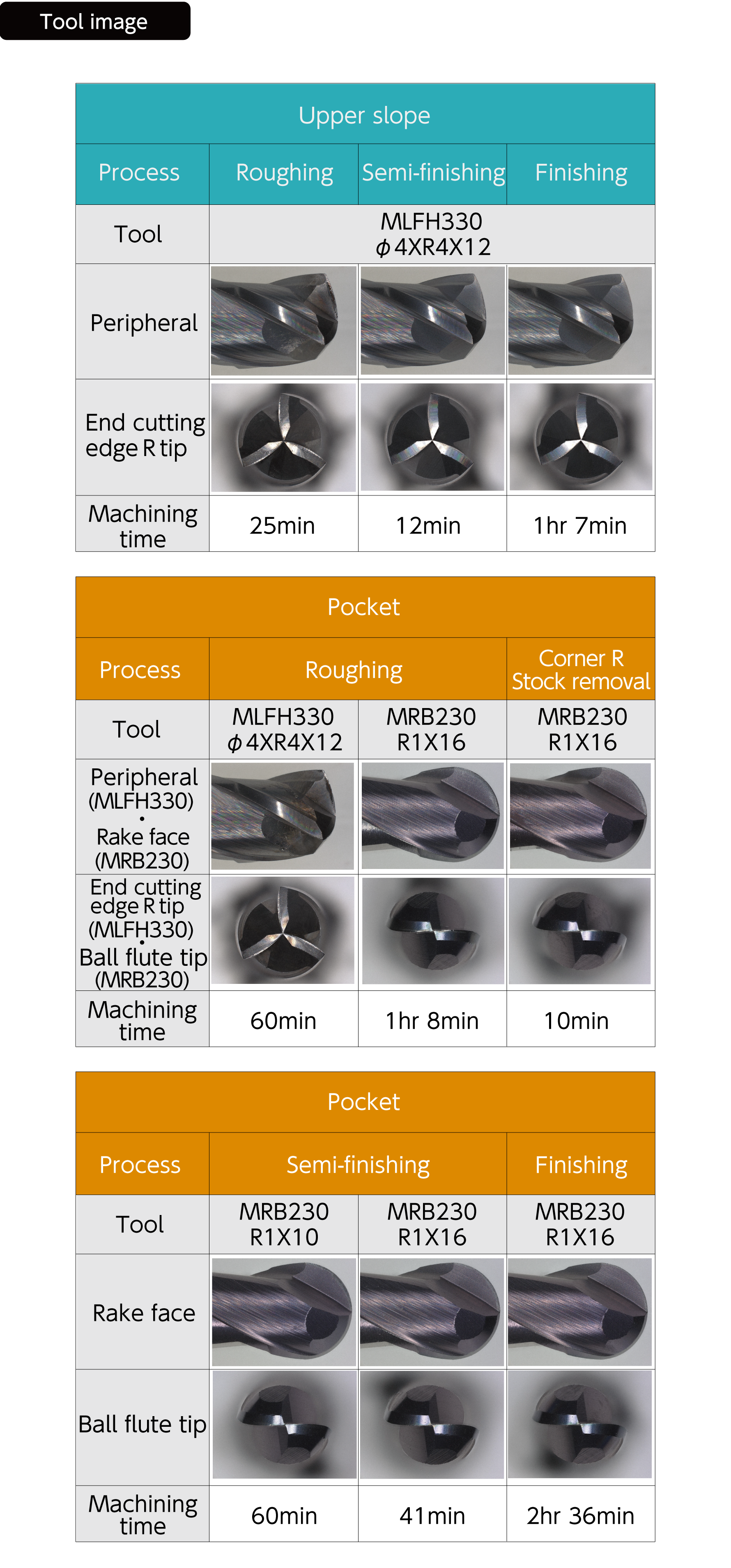

Tool

MLFH330

●Adopt MUGEN COATING PREMUIM for hardened steel to support machining hardened steel up to 65HRC.

●3-flute lens form combines larger pick feed than ball end mills improve machining efficiency.

●High productivity can be achieved by using the 5-axis machining to take large pick feeds while keeping the cut point constant.

MRB230

●The Long neck type is suitable for narrow and deep machining.

●It is possible to have deep and precision three-dimensional cutting in the low to high speed range.

●Total 282 sizes!

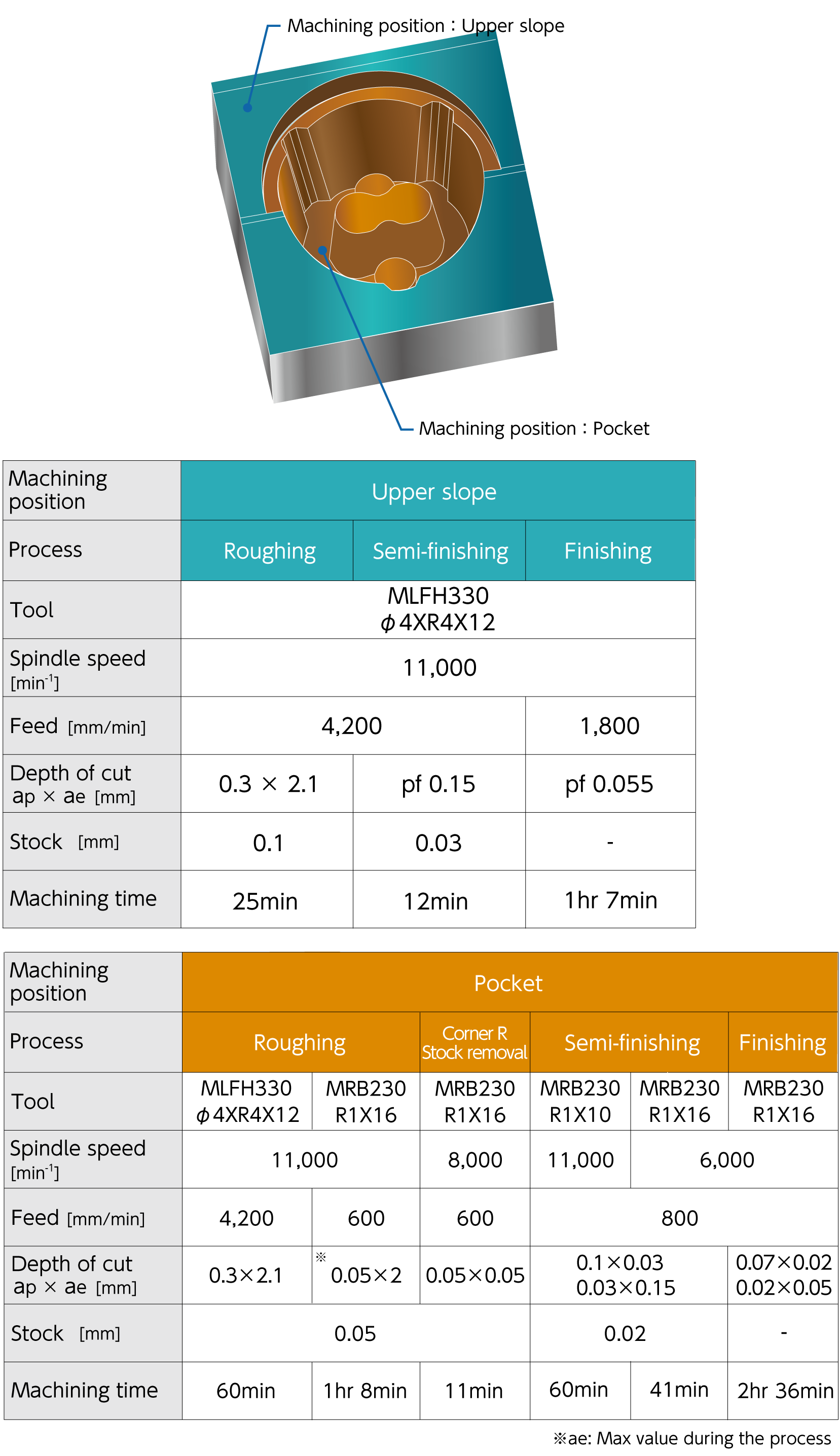

Cutting condition

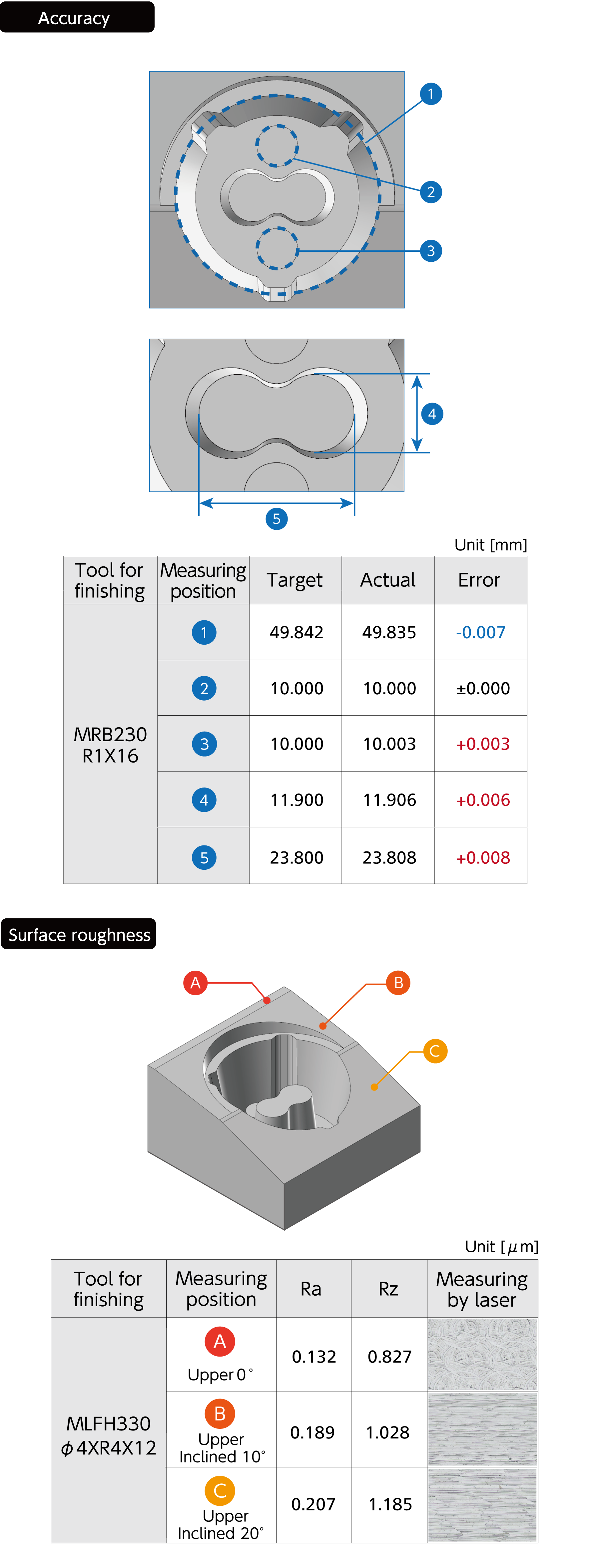

Result

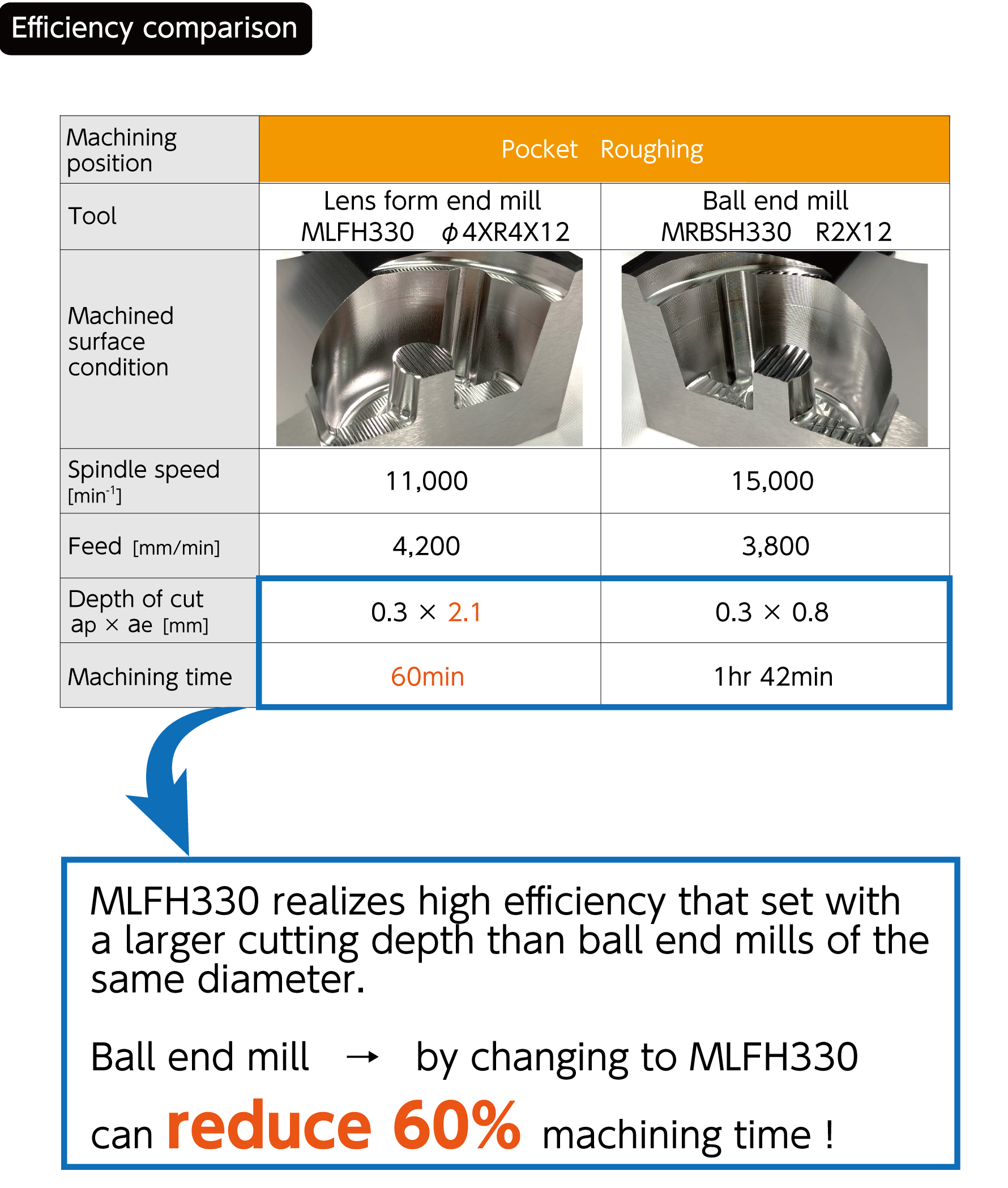

Ball End Mill Comparison