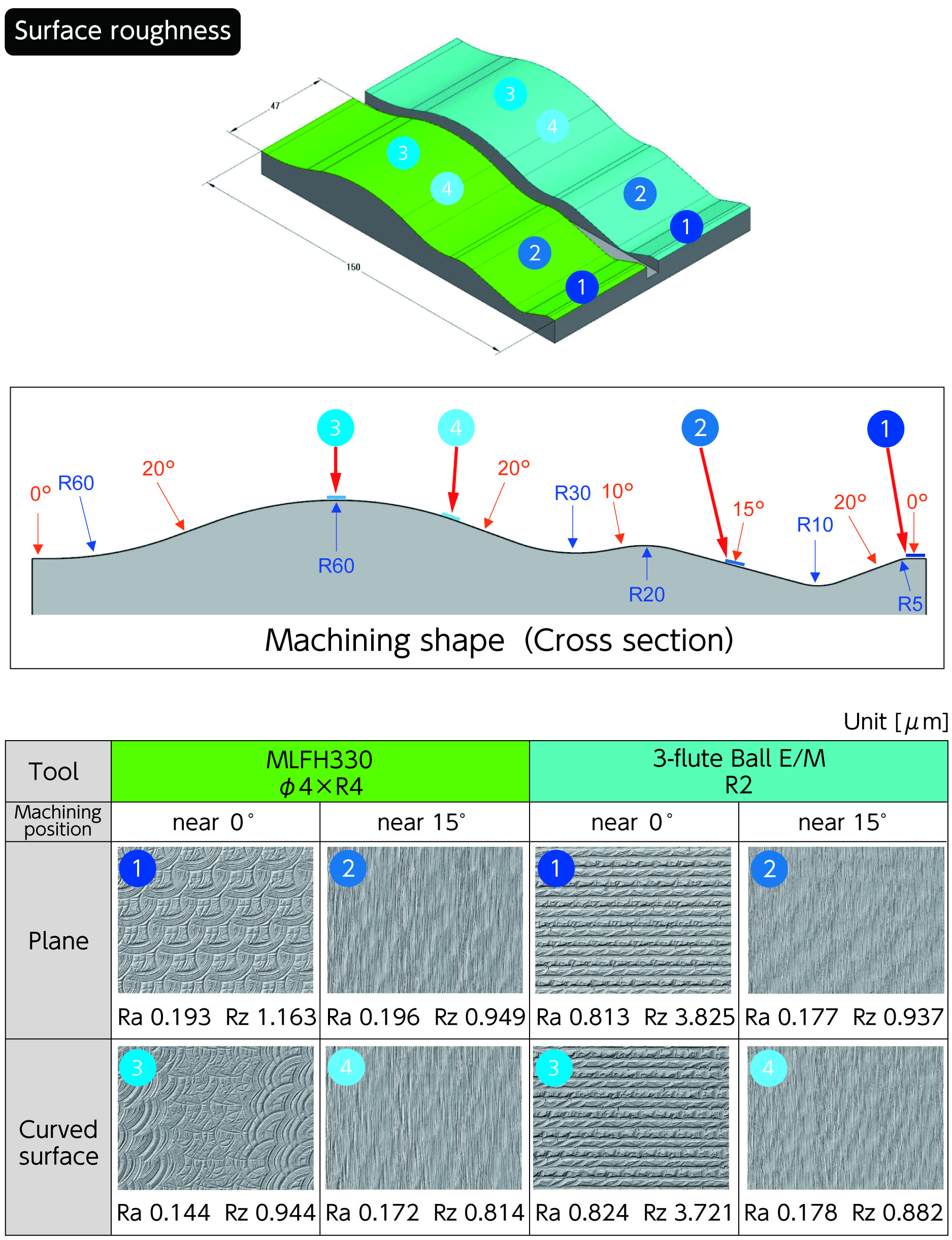

Technology

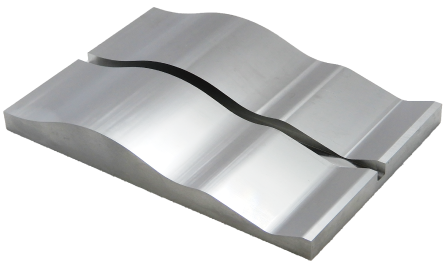

MLFH330 Machining Efficiency Comparison Sample

Work material: STAVAX (52HRC)

Work size: 150x100mm

Machining depth: 15mm

Coolant: Oil mist

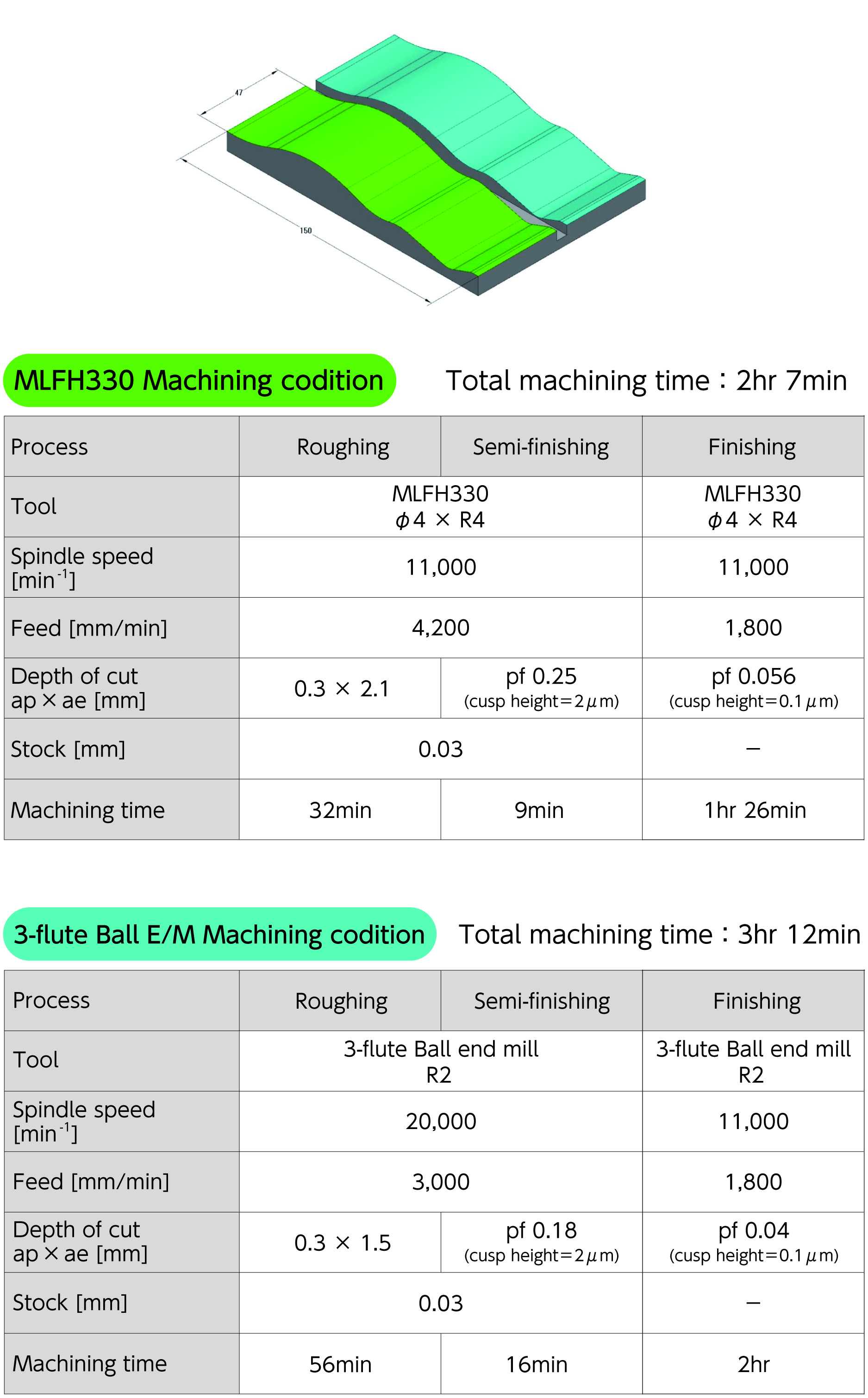

Machining time: 2hr 7min

Tool

MLFH330

●Adopt MUGEN COATING PREMUIM for hardened steel to support machining hardened steel up to 65HRC.

●3-flute lens form combines larger pick feed than ball end mills improve machining efficiency.

●High productivity can be achieved by using the 5-axis machining to take large pick feeds while keeping the cut point constant.

Cutting condition

Result