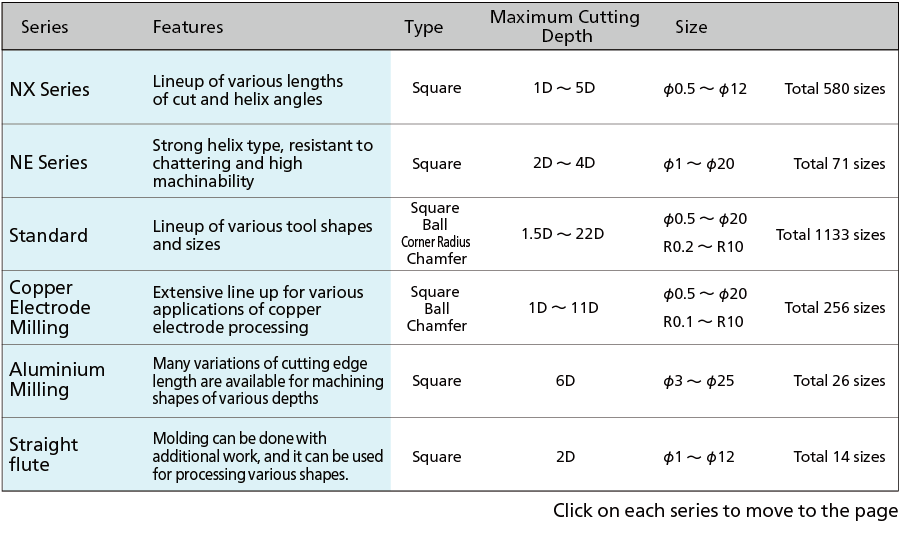

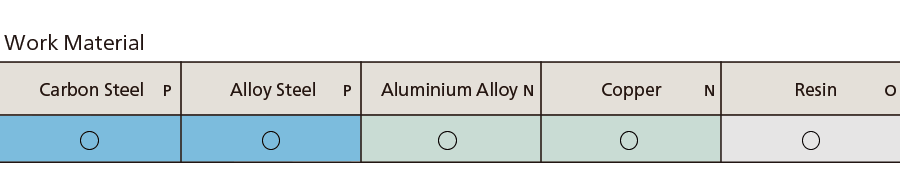

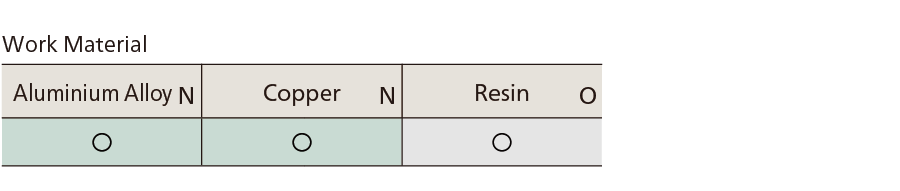

Product

Non-Coating

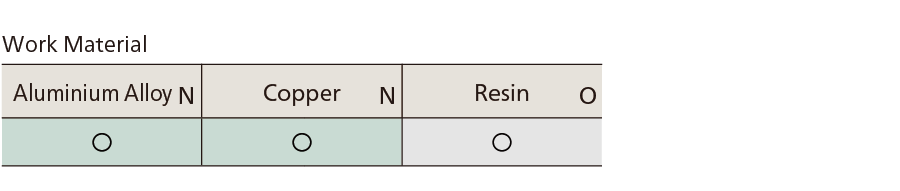

Product

Non-Coating

Lineup

Lineup

Square End Mill

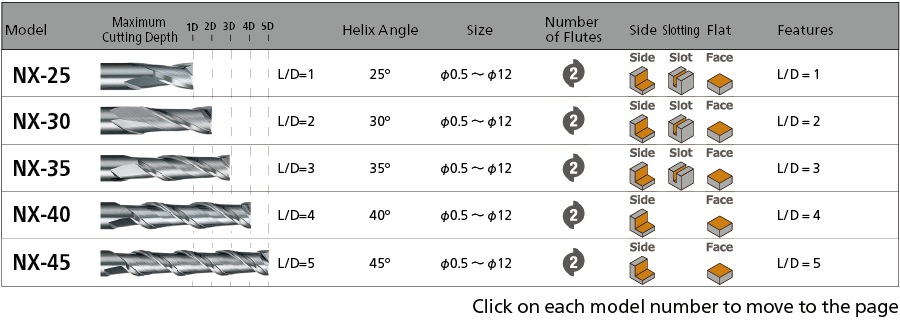

● L/D = 1 and helix 25°.

● Low helix angle minimizes workpiece deflection.

Click here for size variations and recommend milling conditions.

● L/D = 2 and helix 30°.

● Applicable from roughing to finishing on multi-purpose

process.

Click here for size variations and recommend milling conditions.

● L/D = 3 and helix 35°.

● Slightly higher helix angle enables more efficient

machining than standard helix angle.

Click here for size variations and recommend milling conditions.

● L/D = 4 and helix 40°.

● Smooth chip evacuation due to the high helix angle.

Click here for size variations and recommend milling conditions.

● L/D = 5 and helix 45°.

● Side deep part machining can be possible with high

machinability.

Click here for size variations and recommend milling conditions.

Lineup

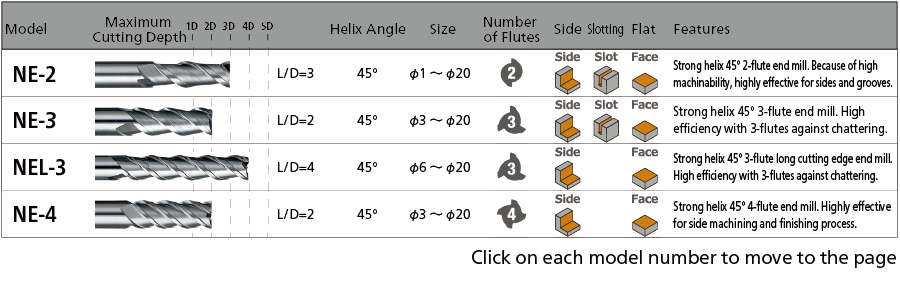

Square End Mill

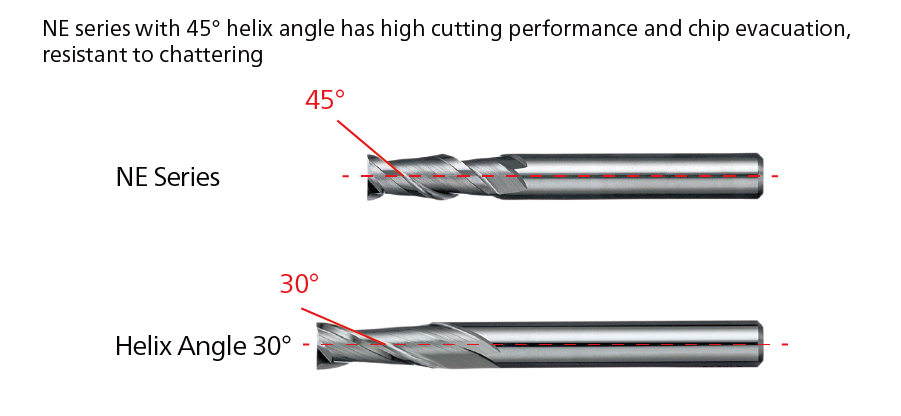

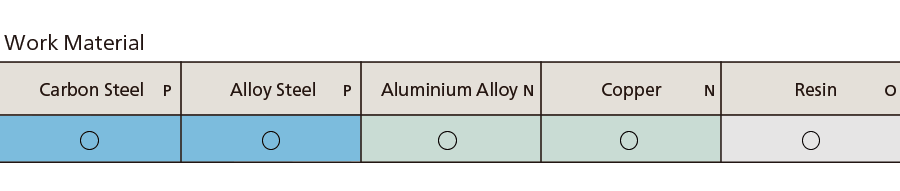

● High helix angle type has high machinability and excellent for side face and slot machining.

Click here for size variations and recommend milling conditions.

● High helix angle type is resistant to chattering and has high chip evacuation performance.

Click here for size variations and recommend milling conditions.

● Long cutting edge length with high helix angle.

● Resistant to chattering and

has high chip evacuation performance.

Click here for size variations and recommend milling conditions.

● Good chip evacuation and best for side machining.

Click here for size variations and recommend milling conditions.

Lineup

Square End Mill

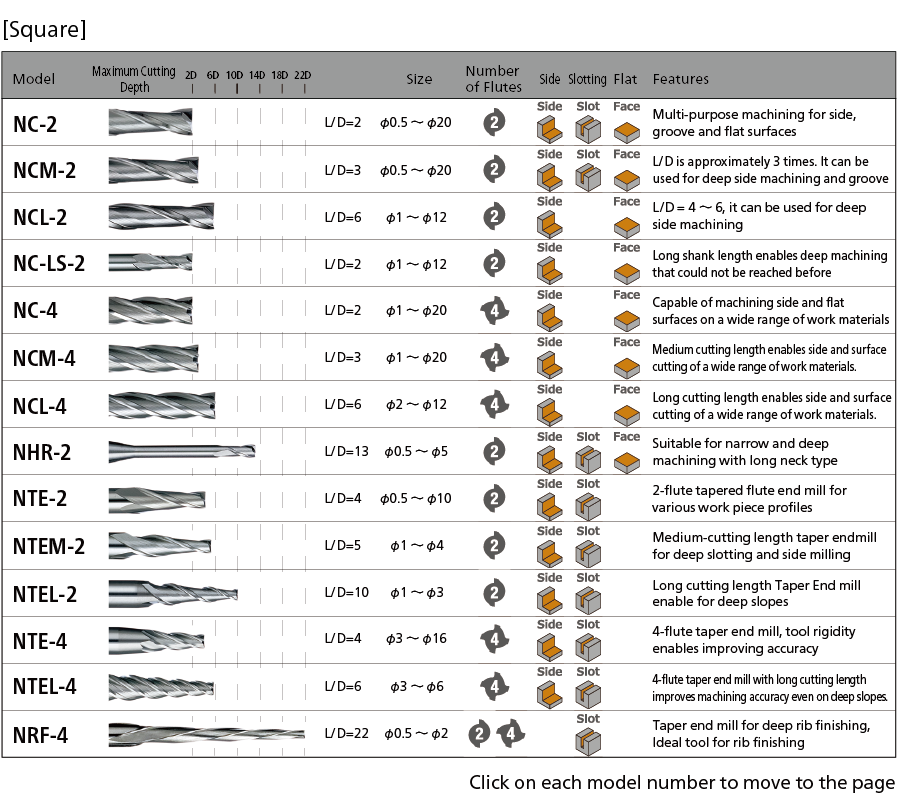

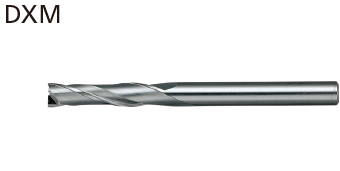

● General-purpose 2-flute end mill.

● Multi-purpose machining for side, groove and

flat surfaces.

Click here for size variations and recommend milling conditions.

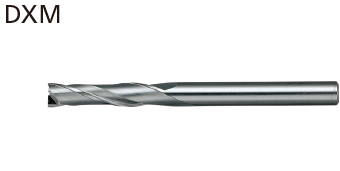

● General-purpose 2-flute medium cutting length end mill.

● L/D is approximately 3

times. It can be used for deep side machining and groove.

Click here for size variations and recommend milling conditions.

● General-purpose 2-flute long cutting length end mill.

● L/D = 4 to 6, it can be

used for deep side machining.

Click here for size variations and recommend milling conditions.

● General-purpose 2-flute long shank end mill.

● Long shank enables deep cutting

that could not be reached before.

Click here for size variations and recommend milling conditions.

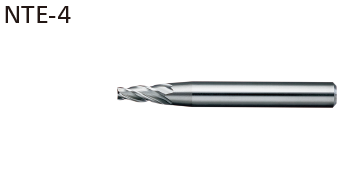

● General-purpose type 4-flute end mill.

● Capable of machining side and flat

surfaces on a wide range of work materials.

Click here for size variations and recommend milling conditions.

● General-purpose 4 flute medium cutting length end mill.

● Capable of machining

side and flat surfaces on a wide range of work materials.

Click here for size variations and recommend milling conditions.

● General-purpose 4-flute long cutting length end mill.

● Capable of machining

side and flat surfaces on a wide range of work materials.

Click here for size variations and recommend milling conditions.

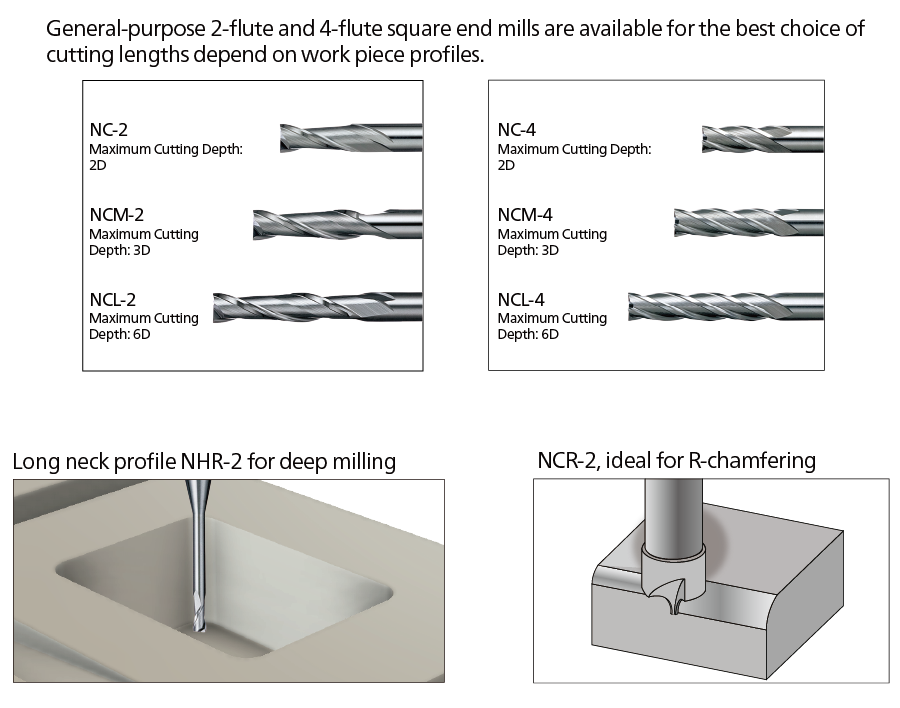

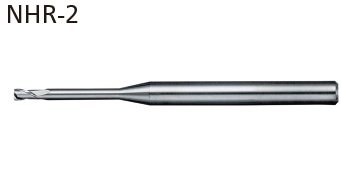

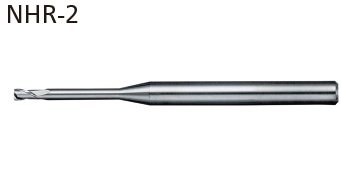

Long Neck Square End Mill

● General-purpose 2-flute long-neck end mill.

● Suitable for narrow and deep

machining with long neck type.

Click here for size variations and recommend milling conditions.

Tapered Square End Mill

● Standard 2-fluteTaper cutting length end mill.

● Extensive lineup for a variety

of sizes.

Click here for size variations and recommend milling conditions.

● Medium cutting edge 2-flute taper end mill.

● L/D = 5 and it enables for deep

groove and side machining.

Click here for size variations and recommend milling conditions.

● Long 2-flute taper cutting length end mill.

● Lineup for deep slopes.

Click here for size variations and recommend milling conditions.

● Standard 4-flute taper cutting length end mill.

● Rigid 4-flutes to improve

machining accuracy.

Click here for size variations and recommend milling conditions.

● Long 4-flute taper cutting length end mill.

● Rigid 4-flute cutting edge

improves machining accuracy even on deep slopes.

Click here for size variations and recommend milling conditions.

● Taper end mill for deep rib finishing.

● Ideal tool shape for finishing ribbed

shapes.

Click here for size variations and recommend milling conditions.

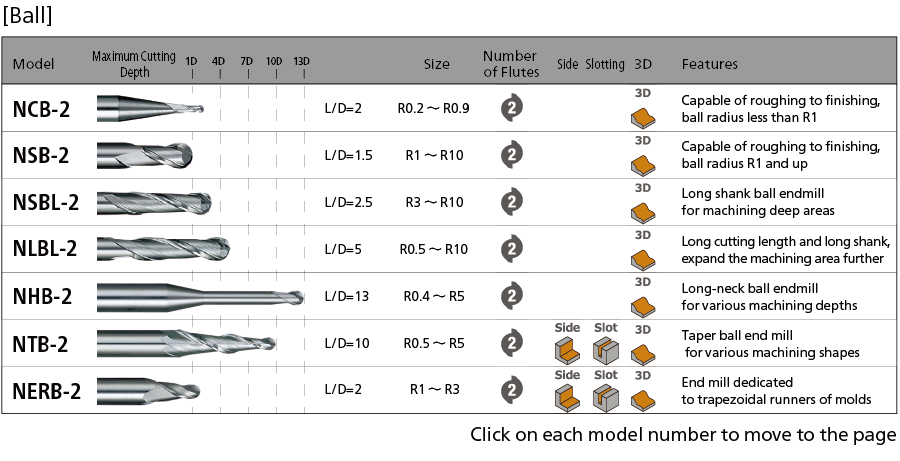

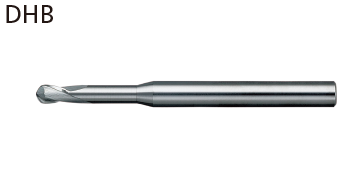

Ball End Mill

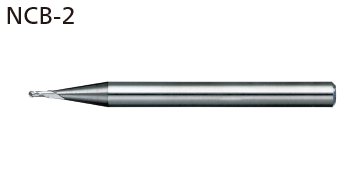

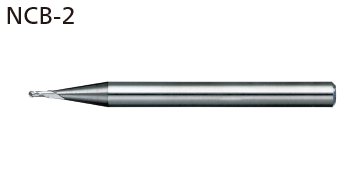

● 2-flute ball end mill specialized for small ball diameters of R1 or less.

●

Versatile type from roughing to finishing.

Click here for size variations and recommend milling conditions.

● Multi-purpose 2-flute ball end mill over R1.

● Versatile type from roughing to

finishing.

Click here for size variations and recommend milling conditions.

● General-purpose 2-flute long shank ball end mill.

● Longer overall length than

NLBL-2, machining to deeper areas available.

Click here for size variations and recommend milling conditions.

● General-purpose 2-flute long neck long shank ball end mill.

● Further expanding

machining possibility with longer cutting edge and long shank than the standard

item.

Click here for size variations and recommend milling conditions.

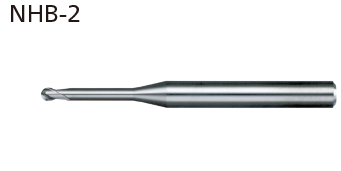

Long Neck Ball End Mill

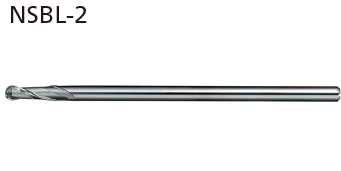

● General-purpose 2-flute long neck ball end mill.

● Abundant size variation for

various machining depths.

Click here for size variations and recommend milling conditions.

Tapered Ball End Mill

● General-purpose 2-flute tapered flute ball end mill.

● Abundant size variation

for various machining shapes.

Click here for size variations and recommend milling conditions.

● End mill dedicated to runner of mold.

● Short cutting edge and high rigidity.

Click here for size variations and recommend milling conditions.

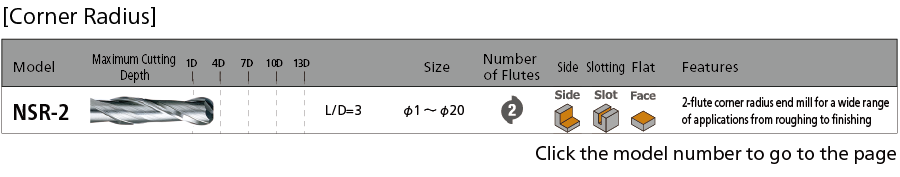

Radius End Mill

● General-purpose 2-flute corner radius end mill.

● Wide range applications for

roughing to finishing.

Click here for size variations and recommend milling conditions.

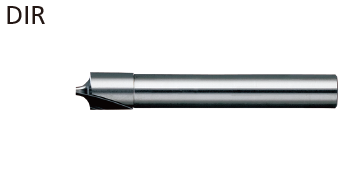

Chamfering

● Specilized for Cutting of Round Chamfering.

Click here for size variations and recommend milling conditions.

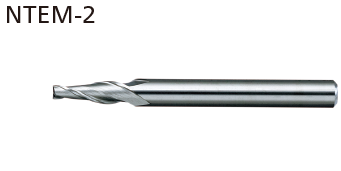

Lineup

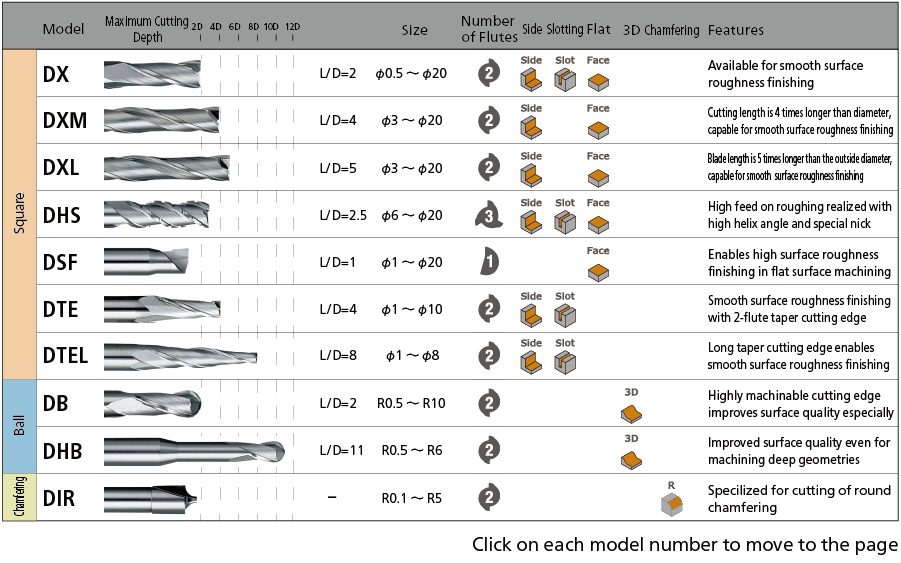

Square End Mill

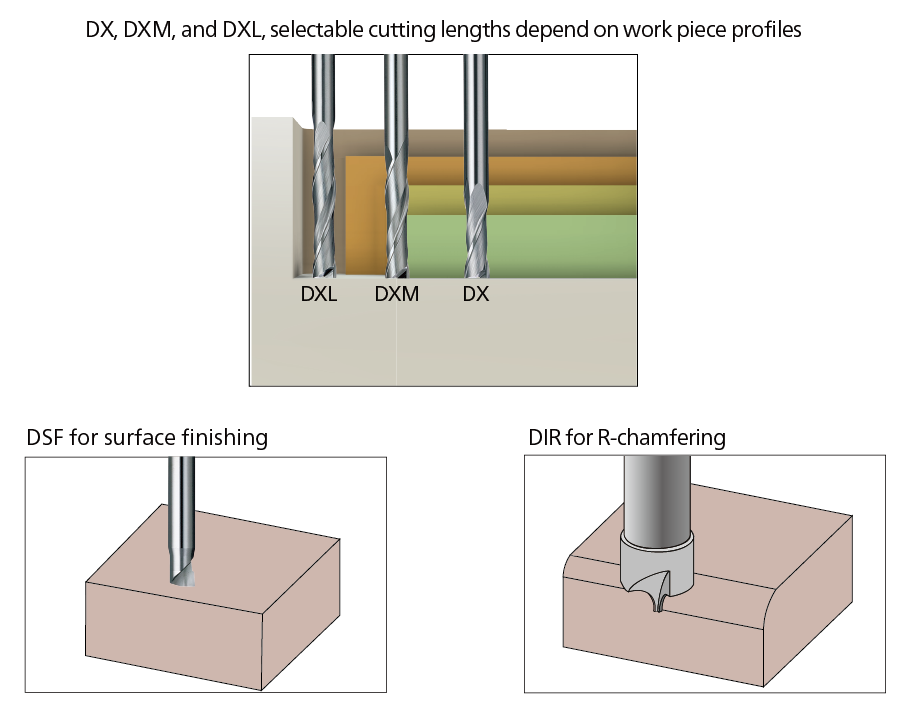

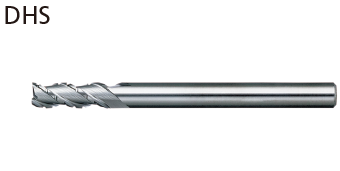

● 2-flute end mill exclusively for non-ferrous metals with high performance cutting

edge.

● Smooth surface roughness finish available.

Click here for size variations and recommend milling conditions.

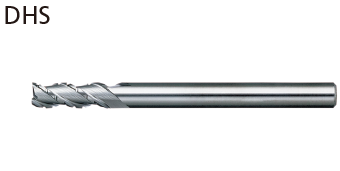

● 2-flute medium cutting length end mill exclusively for non-ferrous metals with high

performance cutting edge.

● Cutting length is 4 times of diameter, achieves

smooth surface roughness finish.

Click here for size variations and recommend milling conditions.

● 2-flute long cutting length end mill for non-ferrous metals with high performance

cutting edge.

● Cutting length is 5 times of diameter, achieves smooth surface

roughness finish.

Click here for size variations and recommend milling conditions.

● 3-flute end mill for roughing with high helix angle and special nick.

● High

feed in roughing.

Click here for size variations and recommend milling conditions.

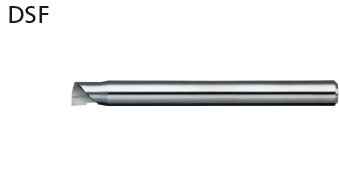

Long Neck Square End Mill

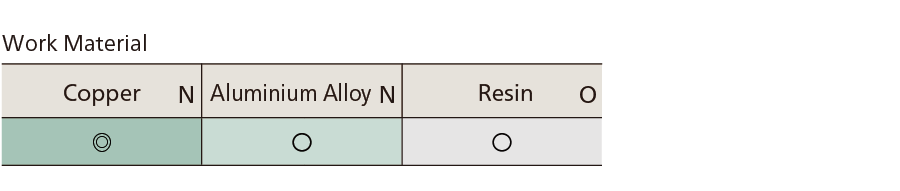

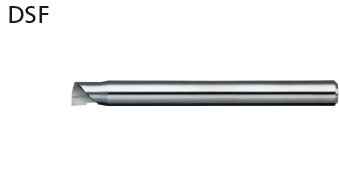

● 1-flute Bottom Finishing End Mill Exclusively for Non-Ferrous Metals.

● Smooth

surface roughness finish available.

Click here for size variations and recommend milling conditions.

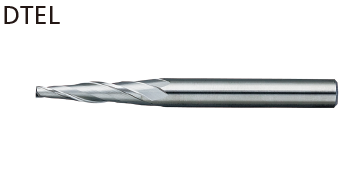

Tapered Square End Mill

● 2-flute Taper Cutting Length End Mill Exclusively for Non-Ferrous Metals.

●

Highly machinable cutting edge shape enables smooth surface roughness finishing.

Click here for size variations and recommend milling conditions.

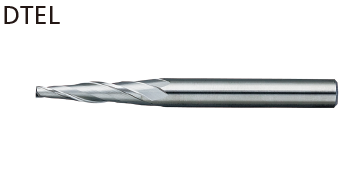

● 2-flute taper end mill for non-ferrous metals with long cutting length.

● Highly

machinable cutting edge shape enables smooth surface roughness finishing.

Click here for size variations and recommend milling conditions.

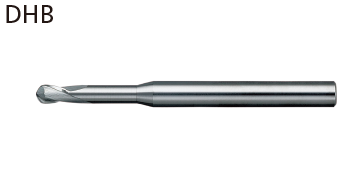

Ball End Mill

● 2-flute Ball End Mill for Non-Ferrous Metals.

● Highly machinable cutting edge

shape improves surface quality.

Click here for size variations and recommend milling conditions.

Long Neck Ball End Mill

● 2-flute Long-Neck Ball End Mill Exclusively for Non-Ferrous Metals.

● Greatly

machinable cutting edge shape improves surface quality even for machining deep

profiles.

Click here for size variations and recommend milling conditions.

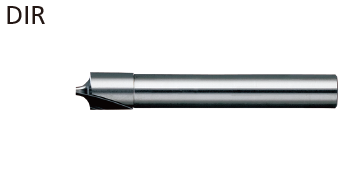

Chamfering

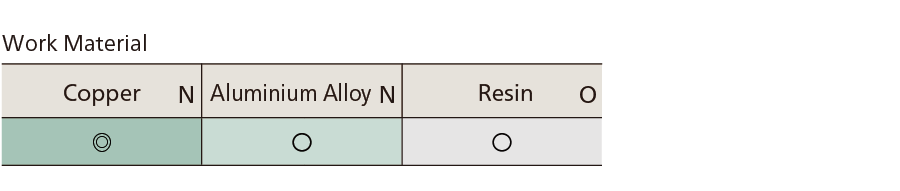

● R-chamfering Cutter Exclusively for Non-Ferrous Metals.

Click here for size variations and recommend milling conditions.

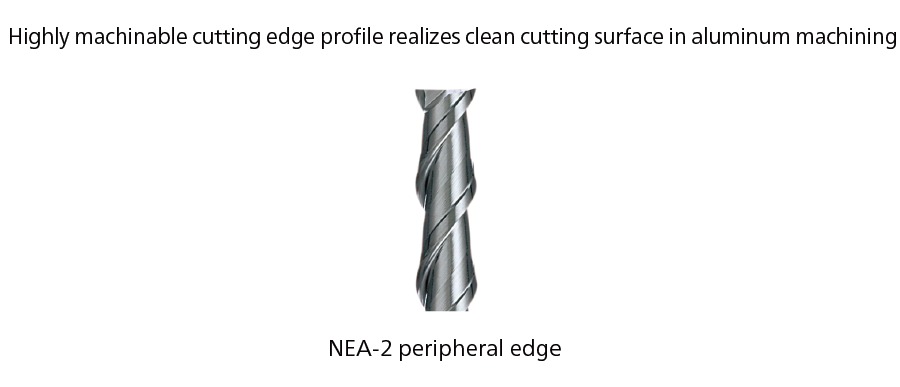

End Mill for Aluminum Machining NEA-2

● 2-flute end mill for non-ferrous metals with a highly machinable cutting edge

shape.

● Many variations of cutting edge length are available for machining

shapes of various depths.

Click here for size variations and recommend milling conditions.

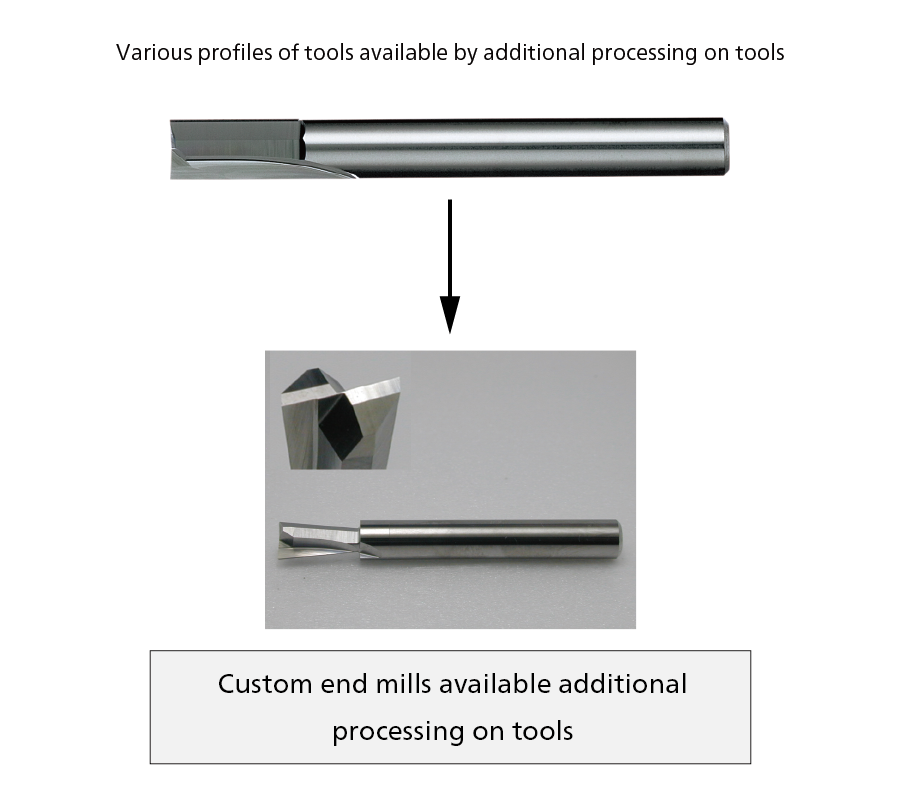

Straight End Mill for Reforming NSL-2

● Forming is possible with additional processing on tools for machining various shape.

Click here for size variations and recommend

milling conditions.