Product

MUGEN COATING Square End Mill

MSE type

Product

MUGEN COATING

Square End Mill

MSE type

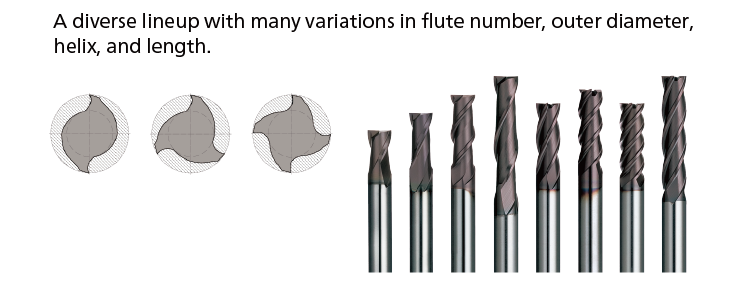

Lineup

● L/D = 1. High rigidity with short length of cut. Suitable for slotting process.

Click here for size variations and recommend milling conditions.

● It is very suitable for high speed cutting due to the length of cut is short and rigid.

● Sharp edge profile guarantees high shearing ability.

Click here for size variations and recommend milling conditions.

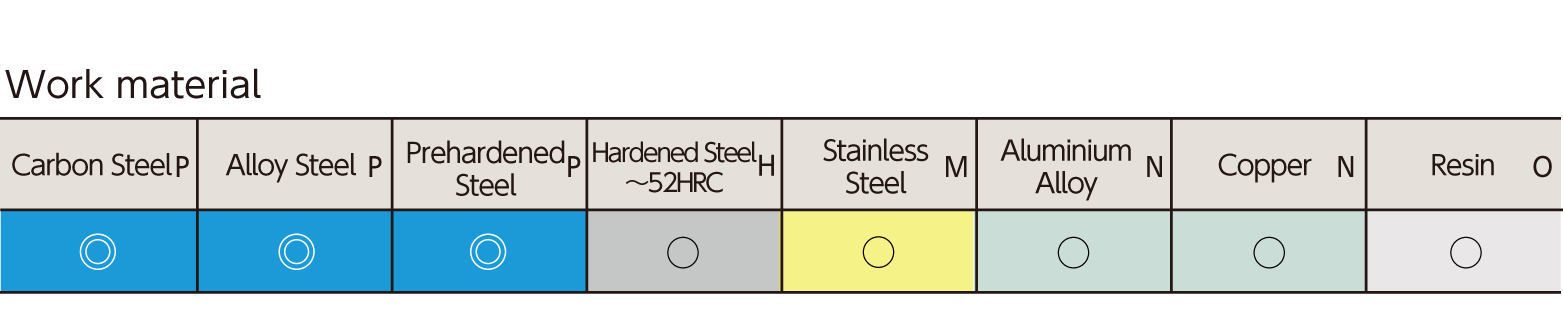

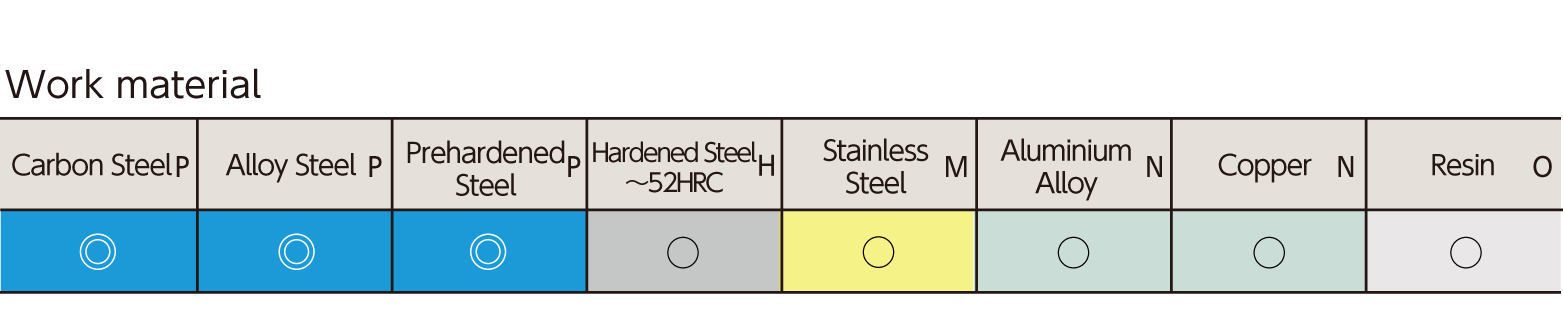

● Our original MUGEN COATING has been put on 2-flute end mill.

● It covers all-round cutting from roughing to finishing.

Click here for size variations and recommend milling conditions.

● L/D = 4 and helix 30°.

Click here for size variations and recommend milling conditions.

● Printed actual measurement of diameter in micron.

Click here for size variations and recommend milling conditions.

● Our original MUGEN COATING has been put on 2-flute end mill.

● Compared with 30° helix angle, it can be reduced cutting load.

Click here for size variations and recommend milling conditions.

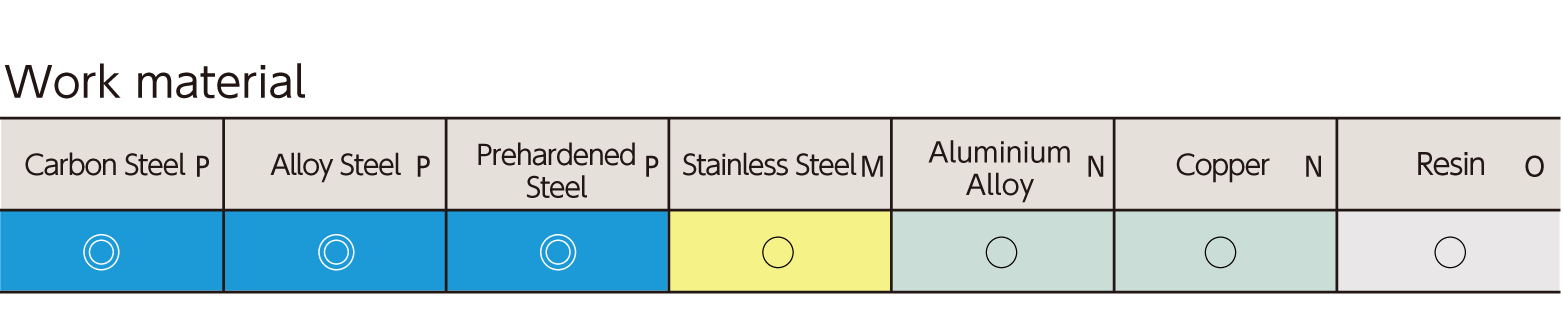

● Our original MUGEN COATING has been put on 3-flute end mill.

● Compared with 30° helix angle, it can be reduced cutting load.

Click here for size variations and recommend milling conditions.

● It can be cut from nonferrous to steels due to the sharp edges.

● Minimize tool deflection for accurate finishing.

Click here for size variations and recommend milling conditions.

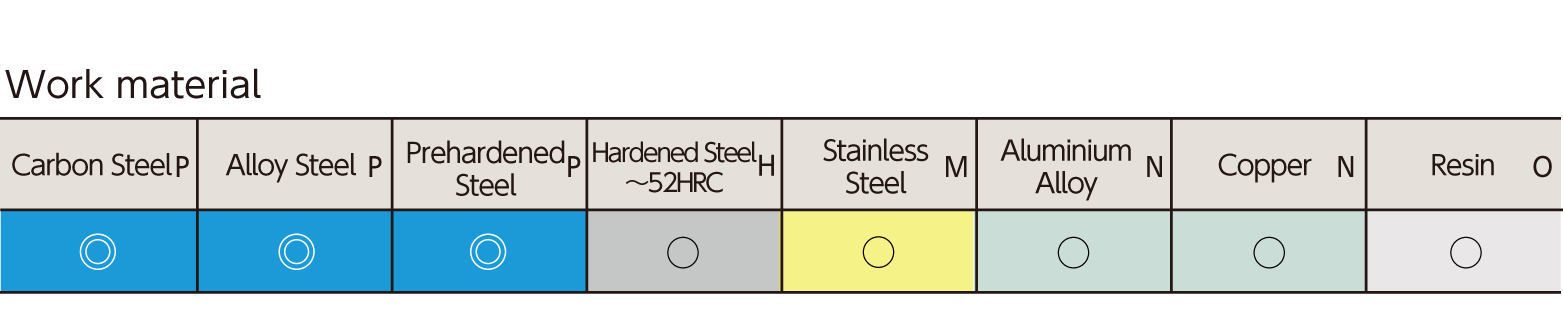

● Our original MUGEN COATING has been put on 4-flute end mill.

● It can be cut from non-hardened materials to hardened materials.

Click here for size variations and recommend milling conditions.

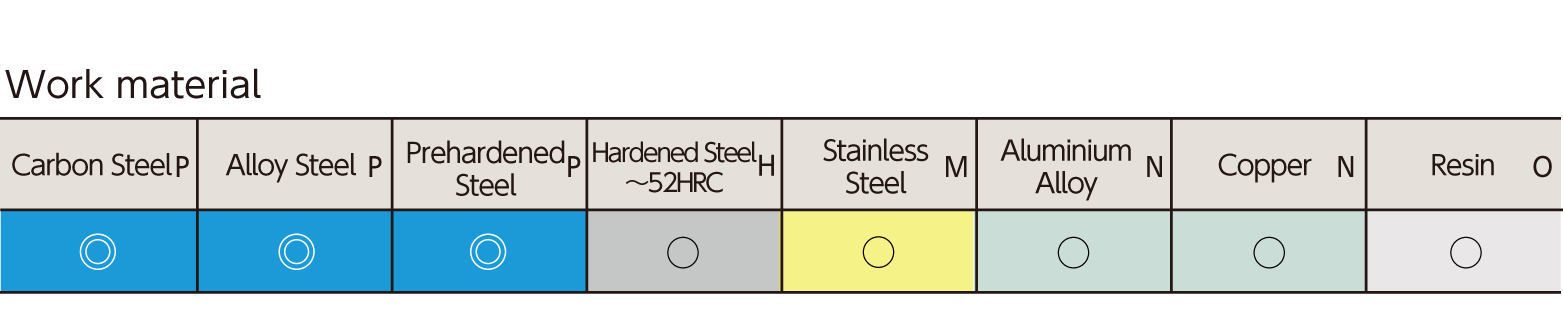

● Our original MUGEN COATING has been put on 4-flute end mill.

● Compared with 30° helix angle, it can be reduced cutting load.

Click here for size variations and recommend milling conditions.

● L/D = 4 and helix 30°.

● It is very suitable for finishing side milling.

Click here for size variations and recommend milling conditions.