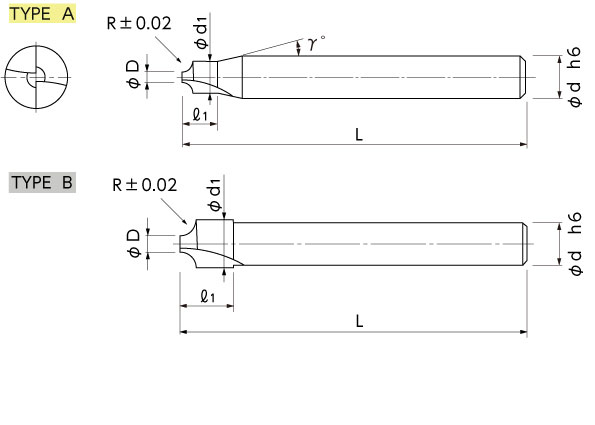

MIR200

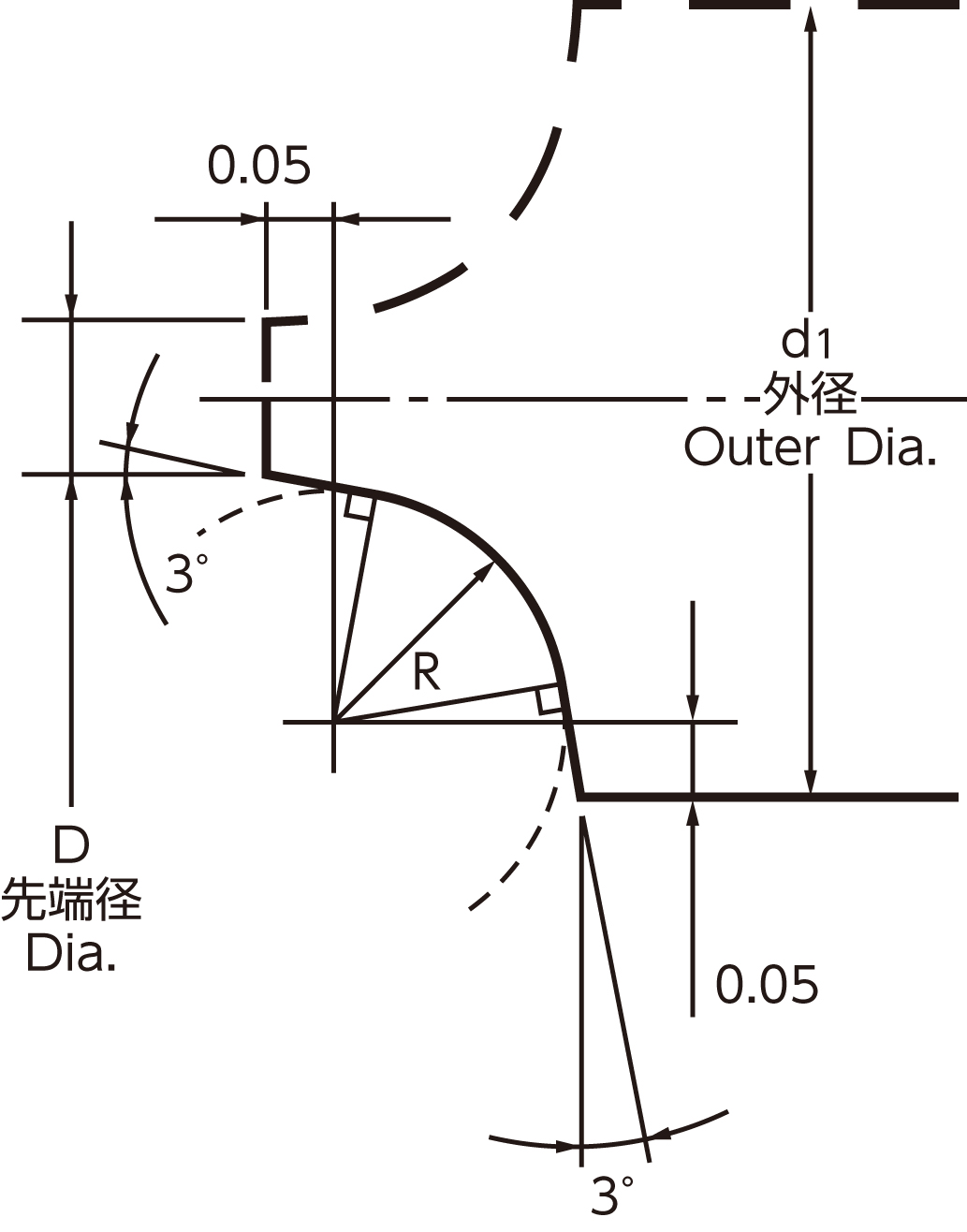

MUGEN COATING 2-Flute Inner Radius Cutter

●It is suitable for both processing NC and MC and can be cut at the corner radius easily.

●Tool life is exceptionally extended as MUGEN COATING provides additional wear resistance.

Coating

MUGEN COATING

Material

Super Micro Grain Carbide

Cutting Possibility of Work Material Hardness

Up to 52HRC

Number of Flutes

2 Flutes

Applications

R Chamfering

Work Materials

Machinable indication by  ,

,

| Carbon Steel | Alloy Steel | Prehardened Steel | Hardened Steel | Stainless Steel | Heat Resistant Alloy | Aluminum Alloy | Copper | Resin | Graphite | Hard Brittle Material | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ~ 52HRC |

~ 60HRC |

~ 65HRC |

~ 70HRC |

||||||||||

| Carbon Steel | Heat Resistant Alloy |

|||

|---|---|---|---|---|

| Alloy Steel | Aluminum Alloy | |||

| Prehardened Steel |

Copper | |||

| Hardened Steel |

~ 52HRC |

Resin | ||

| ~ 60HRC |

Graphite | |||

| ~ 65HRC |

Hard Brittle Material |

|||

| ~ 70HRC |

Hard Brittle Material |

|||

| Stainless Steel | ||||